11.6.

Oil Ratings

The most important property of oil is its thickness or viscosity. Viscosity of oil changes with temperature and it increases with decrease in temperature. The oil must have a low viscosity at low temperatures for starting of the engine. Thick oil at low temperature causes a very high coefficient of friction as can be seen on the right side of the ZN/P curve, Fig. 11.3. If coefficient of friction is too high, the cold engine may not have sufficient energy to carry over from one firing impulse to the next and hence the engine does not start. There is a limit in oil viscosity at any specific temperature at which the engine can start. When the engine is hot, the oil thins and the viscosity lowers. If the viscosity becomes too low boundary lubrication occurs and decrease in coefficient of friction takes place as can be seen on the left end of the ZN/P curve. Motor oil must have its viscosity between these two extremes. The oil must allow the engine to start when cold and must have enough viscosity to develop correct hydrodynamic lubrication film at normal operating temperature. The change in viscosity between the cold and hot oil viscosities is called viscosity index. Oils with a high viscosity index are less thin than oils with low viscosity.

The viscosity of oil is determined by one of several types of viscosimeters. The oldest and

Fig. 11.5. Schematic ofaSaybolt viscosimeter.

most familiar viscosity measurement device is the Say bolt viscosimeter (Fig. 11.5). It uses an accurately machined brass tube with a calibrated opening in its bottom called a Universal orifice. The tube is immersed in a bath, and is maintained’ at the test temperature. The tube is fitted with a stopper at its lower end and filled with the sample oil. When the test temperature is reached, the stopper is pulled from the tube, allowing the sample to flow through the Universal orifice. The viscosity from this test is reported as Saybolt Universal Seconds (SUS). Minimum friction occurs when the viscosity is from 30 to 40 SUS at the operating temperature. Two test temperatures are used to classify lubricating oil, 255 K (-18 degree C) and 372 K (99 degree C). The 255 K test indicates the oil viscosity at low temperatures and 372 K test indicates the oil viscosity at normal engine operating temperature.

Fig. 11.6. Schematic of glass kinematic viscosimeter.

Viscosity measurement by the Saybolt viscosimeter is quite time consuming. An alternate easy and faster method incorporates a test procedure for opaque liquids and the results are reported in centis-tokes, the designation for kinematic viscosity. In this test (Fig. 11.6), a measured amount of oil sample is drawn into a glass viscosimeter tube, which is then placed in a 377 K bath. The top of the sample is drawn slightly above two test lines. The time taken by the sample to drain from one test line to the next is measured in seconds. The seconds are multiplied by the viscosimeter correction factor to get the viscosity value in centistokes. This test is repeated number of times for accuracy without draining the viscosimeter tube.

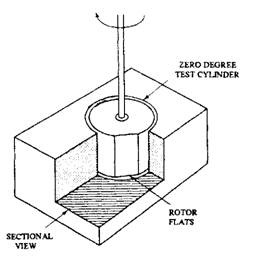

Another test procedure uses Cold Cranking Simulator (CCS), which replaces the Saybolt viscosimeter for 255 K tests. The CCS (Fig. 11.7) has a rotor, with two flats, which is placed in a cylinder. The cylinder is then filled with the sample and the whole unit is cooled to 225 K. At this test temperature, the rotor is turned by a constant speed motor. The torque required to turn the rotor is reported in centipoise, a measurement of absolute viscosity. This test is also quicker and simpler than the Saybolt viscosity test.

Fig. 11.7. Schematic of a cold cranking simulator.

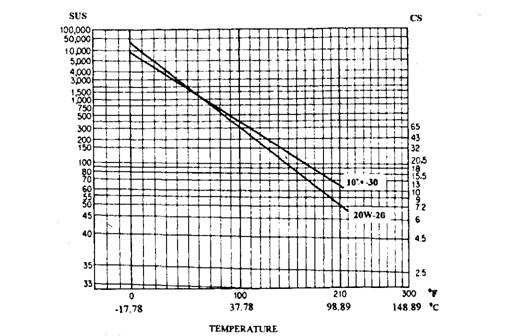

Fig. 11.8. Viscosity-temperature chart.

For many years, organisations such as the Society of Automotive Engineers (SAE), the American Petroleum Institute (API), and the American Society for Testing and Materials (ASTM) have worked together in standardizing oil ratings and oil classifications. Lubricating oils are sold with an SAE number since 1911. This number indicates the viscosity range in which the oil fits. Oils tested at 255 K are given an SAE number, followed by the letter “W”, which indicates a winter grade of oil. Oils tested at 372 K have a SAE number without a following letter. SAE 40 indicates that the oil has only been checked at 372 K and falls within this grade classification when hot. SAE 20 W-20 indicates that the oil has been tested at both 255 K and 372 K and falls into respective classifications. An SAE 10W-40 multigrade oil is one that meets the SAE 10 W specification when cooled to 255 K and meets the SAE 40 classification when heated to 372 K. Mutli-grade oils must have a higher viscosity index than straight grade oils. SAE viscosity classifications are 5W, 10W, 20W, 20, 30, 40, and 50. Viscosity plotted on a standard viscosity temperature chart is shown in Fig. 11.8.