22.12.

Independent Front Suspension System

To overcome disadvantages associated with the rigid-beam-axle suspension, independent front suspension (IFS) is used. The term independent suspension describes any system that connects the wheels to the frame in which the movement of one wheel has no effect on the other wheel. The advantages and disadvantages of adopting independent front suspension for passenger cars and light vans include the following:

Advantages.

(a) The centrifugal force is created in sprung vehicle bodies when cornering forms a roll couple that tilts or rolls the body outwards. The body roll is encountered by a resisting couple, produced by the product of the springs’ reaction forces and effective distance between them. Therefore, the necessary reaction stiffness of the spring to resist the roll couple increases or decreases as the effective distance between the springs decreases or increases respectively. In fact the roll angle is inversely proportional to the square of the effective spring-base width.

In case of the beam axle, the greatest distance between the springs depends on the width of the chassis, which supports the shackles attached. But with the independent suspension using transverse-arm linkage, the effective distance between springs equals the vehicle’s wheel track. Therefore compared to the axle-beam, relatively softer springs can be used with independent suspension without affecting body roll. The soft springs respond and deflect with the smallest road deformation without transmitting the shocks to the vehicle body and passengers, and hence provide better ride comfort.

(6) As the elastic strain energy stored in a coil or torsion-bar spring is greater than for a semi-elliptic multi-leaf spring for a given spring weight, lighter springs can be used with independent wishbone suspension. In the case of independent wishbone suspension, the spring is required only to support vertical loads and to absorb shocks, because the suspension linkage alone sustain the driving, braking and lateral forces. With the wishbone hinging on the sub-frame structure, the unsprung stub-axle swivel-joint follows arcs relative to the sprung body structure when the suspension bounces. These arcs produce a precise and predictable wheel-path in the vertical plane, which is essential for consistent steering geometry.

(c) Since the independent suspension has less unsprung mass, road-wheels follow the contour of the road irregularities up-to higher speeds than for the heavy rigid-axle-beam suspension. As a consequence, tyre scrub and wear are reduced with independent suspension.

(d) An anti-roll bar, if used in conjunction with the independent suspension, provides the necessary resisting stiffness to oppose body roll during cornering and hence softer springs can be employed for normal vertical loads.

(e) If a separate or independent suspension for each side of the car is used, any interaction between opposite road-wheels is reduced, so that there is less chance of wheel wobble due to vibrational resonance.

(/) The engine and chassis structure can be lowered so also the centre of the car so that

the engine can be moved forward to provide more room for the passengers. (g) Independent suspension usually lowers the roll centre, hence the body rolls before the wheels break away from the road, providing a warning to the driver.

Disadvantages.

(a) The wheel cambering with body roll reduces concerning power.

(b) There is a slight change in wheel track, causing tyre scrub during bouncing of one wheel.

(c) A more rigid chassis or sub-frame structure is required.

(d) A more complicated suspension and steering linkage and pivot joints are necessary, so that the suspension becomes more expensive and tends to wear more.

(e) Effects of unbalanced-wheel-assembly are transmitted to the steering-wheel more easily and are also more pronounced.

(f) Steering-geometry alignment is more critical and requires more frequent attention. 22.12.1. Types of Front Independent Suspension

Double-transverse Wishbone Suspension.

Figure 22.57 jllustrates the main details of this suspension. In this system, two links, usually parallel in the normal ride position, are constructed in a wishbone shape to provide fore-and-aft stiffness and to resist braking torque. Each wishbone uses three bearings, two inner bearings connecting with the frame and an outer one attaching to the stub wishbone, and the upper end to a point on the frame just above the upper wishbone. The vehicle weight and the payload is transferred from the sprung body and cross-member to the top of the coil spring. A damper is intalled inside the coil spring and is attached by rubber bushes to the underside of the fixed cross-member and to the lower wishbone member. Side thrust, if any, is resisted by stiffness of the wishbone members and the swivel-joints and pivots.

The front of the car ‘drives’ towards the ground when the brakes are applied, because the lower wishbone pivot points on the link-type system are normally set parallel to the road. To minimise this problem, anti-dive geometry is used in which the rear pivot point of the lower wishbone is placed higher than the front pivot. During application of the front brakes, the braking torque on the inclined wishbone produces a vertical force, which counter balances the extra load transferred from the rear to front wheels.

Fig. 22.57. Transverse double wishbone suspension.

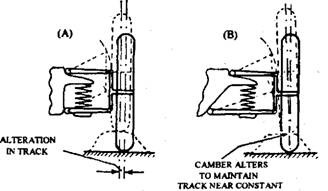

When car is cornering, the body rolls and both wheels lean outwards from the turning circle, producing a small amount of camber roll (Fig. 22.58A). During travelling in straight ahead position, if one of the wheels goes over a bump or pot-hole in the road, only the individual suspension linkage is momentarily deflected up or down without altering the average height of the sprung body (Fig. 22.58B). As a consequence, this provides a completely independent suspension for each wheel so that reaction vibrations are not transmitted from one side to the other.

Fig. 22.58. Effects of body roll and irregular road surfaces on transverse double wishbone suspension. A. Both wheels tilt outwards B. Body remains upright when wheel body rolls. enters pothole and tilts inwards.

Constant-track Unequal Double-transverse-wishbone Suspension.

In this layout, the stub axle carrier is connected to the frame by two links. A semi-trailing radius rod resists longitudinal dynamic loads and braking torque. The spring can be placed above the top axle carrier. Rubber or plastic (PTFE) bushes are installed at the inner ends of the wishbone. Usually a ball joint is positioned at the outer end to enable the stub axle to swivel. Coil springs are intalled in the position shown or above the upper wishbone.

Fig. 22.59. Content-track unequal double-transverse wishbone suspension. A. Transverse equal-length. B. Transverse unequal-length.

Wishbones of equal length (Fig. 22.59A) are used in early designs; as a consequence the track variation caused considerable tyre wear. To minimize this wishbones of unequal length (Fig. 22.59B) are fitted, the longer one at the bottom; however changes in camber angle are now produced. By mounting the upper wishbone slightly behind the lower one, a constant caster angle can be obtained. The wishbone axis is sometimes inclined towards the rear to obtain the maximum wishbone length without restricting engine space.

Either a piston-type damper is used to mount the inner bearings for the top wishbone, or a telescopic damper is intalled in the centre of the coil spring. When a torsion bar spring is used,

a large movement of the telescopic damper is obtained by fitting the damper diagonally. In this layout, the lower end is joined to the outer end of the lower link, or a torsion bar is connected to the inner ends of the lower link.

MacPherson Suspension.

In this type of suspension (Fig. 22.60), a long telescopic tube, incorporating the damper, is pivoted at the upper end and rigidly connected to the stub axle at the lower end. A single transverse link, attached to the frame by rubber bushes and connected to the stub-axle by a ball joint, provides track control. The coil spring is installed between the fixed and floating suspension members. A stabilizer bar interconnects both front suspension lower links and also provides the required fore-and-aft stiffness. The ball and socket joint at the bottom serves as a pivot for the steering strut and the stub-axle in the horizontal plane. This joint also serves as a suspension joint for relative movement between the track-control arm and stub-axle in the vertical plane.

Similar to several other suspension systems, castor, camber, and swivel-axis inclination are set during manufacturing and cannot be altered. The swivel-axis inclination is the angle formed between the vertical and the line taken from the centre of the strut thrust bearing to the centre of the ball joint, which connects the strut to the track control arm. The strut is set to a smaller angle than the swivel axis inclination for providing tyre clearance.

By the top of the strut towards the vehicle centre, it is possible to obtain a negative offset (negative scrub radius) for the steering. When the coil spring is almost fully compressed, a bump stop installed at the top of the piston rod serves to stiffen the suspension springing. The triangular track-control arm absorbs driving and braking thrust reactions.

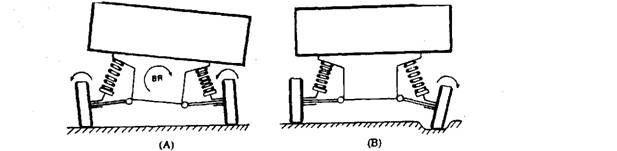

During cornering, the body rolls and the inner outer wheels respectively lean outwards and inwards depending on the initial angular set of the transverse track-control arm. Consequently, both wheels produce camber roll (Fig. 22.61A). Each wheel suspension is totally independent of the other side, due to which the suspended body is not influenced by small wheel deflections during movement of the car (Fig. 22.61B).

Fig. 22.60. MacPherson leg-strut suspension.

Fig. 22.61. Effect of body roll and irregular road surface on MacPherson suspension. A. Wheels tilt towards the centre B. Wheel enters pot-hole and tilts inwards during body roll. and body remains upright.

Short Swinging Arm.

This is the simplest type of independent suspension system. This uses only one transverse arm, which is known as a wishbone member and is held rigidly to the wheel stub-axle, through a king pin steering joint while pivoting on the body sub-frame. The wishbone-arm forks are spread wide apart at the pivot points to absorb any driving- and braking-reaction torque solely by the swinging arm member. The spring, installed between the body structure and the swinging arm, supports only the vehicle’s weight. The swinging arm and the supporting sub-frame pivot points completely absorb side-forces and reactions.

The body rolls when the vehicle moves on a curved track, so that both wheels lean inwards towards the centre of the circular path (Fig. 22.62A), producing camber roll. When one wheel follows a dip or an obstacle, the associated deflection is confined to one side of the car only and the spring is compressed without disturbing the body height to an great extent (Fig. 22.62B). With this suspension, the slightest swing of the arm considerably alters the uprightness of the wheel to the ground. __ _

Fig. 22.62. Short swinging arm. A. Both wheels tilt inwards during body roll.

B. Wheel enters pot-holes and tilt outward and body remains upright.

Torsion-bar Double-transverse-arm Suspension.

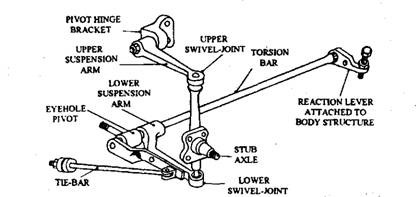

An alternative version of transverse-double-wishbone suspension incorporates a torsion-bar spring in place of a helical coil spring so that the elastic resistance is provided to changing suspension vertical load (Fig. 22.63A). The torsion bar is located parallel to the under-frame longitudinal members on each side of the vehicle. One end of the torsion bar is splined to a reaction lever, bolted to the under-side of the body, while the other end is splined to the lower suspension arm supported by the eyehole pivot.

During deflection of the suspension, the lower suspension arm pivots and twists the torsion bar, which is resisted by the rigidly held reaction lever at the far end of the bar. The upper suspension arm completes the four-bar-chain geometry due to which the resultant stub-axle vertical movement always keep both front road-wheels approximately perpendicular to the ground. In some systems, the upper suspension-arm pivot forms part of a lever type damper unit, in others a separate telescopic damper is installed between the sub-frame and the lower suspension arm.

The eyehole pivot assembly permits the lower suspension arm to pivot as well as transfers torsion-bar resilience to the suspension (Fig. 22.63B). The lower suspension pivot has a one-piece circular eyehole casing and stud bolted to the sub-frame. A splined eye-bolt is located at the centre of the sleeved bush, which is pressed into casing. When the lower suspension arm partially rotates, the torsional distortion of the rubber takes up entire angular movement so that frictional sliding between the eye-bolt and the inner bush sleeve is avoided.

Fig. 22.63. Torsion-bar double-transverse-arm suspension.

Static and dynamic elastic resistance is transferred by the torsion bar’s end splines located in the same internally splined hole in the lower suspension arm as in the splined eye-bolt. Hence the torsion bar acts only as a spring and does not pivot the lower suspension arm. A tie-bar supports the lower suspension arm and also prevent horizontal twisting to this arm during acceleration and braking of the vehicle.

The trim height of the vehicle can be altered by screwing in or out the adjustment set-bolts of the torsion-bar reaction-lever. Body-roll and bump or dip deflection of the suspension causes wheel tilt similar to that shown in Fig. 22.58. The overall simplicity and compactness of the suspension with torsion-bar spring is quite simple and compact and hence is opted for car applications.