15.8.

Heavy Vehicle Starter Motors

An engine with a capacity of more than 3 L requires a large starting motor, specifically for a compression-ignition (CI) engine. CI engines must be cranked at a speed of at least 100 rpm

to initiate combustion. Due to a very high compression ratio in CI engines, the maximum torque required is greater than a petrol engine. The high pressure in the cylinder accelerates the piston rapidly during its downward movement. This causes considerable variation of both the rotational speed and the resisting torque loading on the starter motor.

To achieve high starting power heavy vehicles normally use a 24 V system. For a given electrical power requirement, the doubling of the voltage compared with a 12 V systems, reduces the current by half. Without the extra 12 volts, the current load on the battery and starter circuit becomes exceptionally high, especially on a cold morning in winter. Another problem associated with large engines is the requirement of high torque to overcome breakaway and inertia of the heavy parts. It also needs a strong drive system and the pinion of this system must be fully meshed with the ring gear before the motor is fully powered. Two types of motor and drive system in use are (i) axial (sliding armature), and (ii) coaxial (sliding gear).

Fig. 15.27. Construction of axial starter.

15.8.1.

Axial (Sliding Armature) Starter Motor

The main features of this type starter motor are its size and robust construction. For the engagement of the pinion to the flywheel ring gear, the complete armature assembly slides axially through the motor casing. A simplified construction of the starter is illustrated in Fig. 15.27. In the figure, the motor is shown in the rest position. The armature is held by a spring so that it is offset to the field poles. When the field is energized, the armature is pulled to the left and the pinion is slid into engagement with the ring gear.

Figure illustrates the electrical circuit of the starter motor, which uses three field windings. The main winding as usual is of thick-section and low-resistance winding, and is connected in series to the armature. The auxiliary winding is wound with thinner wire so that it has a relatively high resistance, and is also connected in series with the armature but in parallel with the main winding. The holding winding is also a high-resistance winding but is connected in parallel with the armature as well as with the other two windings.

A two-stage solenoid switch, mounted on the starter operates the starter, and is energized by the driver’s

Fig. 15.28. Circuit of axial motor.

^switch. When the switch is operated, the first pair of contacts closes but the second pair is held open by a pawl that engages in a slot in the trip lever. Once the pinion is near fully engaged with the ring gear, the pawl allows the second pair of contacts to close.

Figure 15.29 illustrates the operation of the motor. Figure 15.30A shows the first pair of contacts is closed, which energizes the auxiliary windings, holding windings and armature. The armature rotates slowly and moves axially so that it is central to the field poles. Simultaneously,

the pinion is slowly slid into mesh with the ring gear. When the pinion is on the verse of its full engagement, the release disc on the armature strikes the pawl so that the trip lever closes the second pair of contacts (Fig. 15.29B). Now current passes through the main windings, causing the motor to develop its full torque.

Fig 15-29. Action of axial motor. A. Closure of first contacts. B. Closure of second contacts.

As cranking speed rises, the current through the main and auxiliary windings decreases due to back emf generated by the rotating armature, especially when engine fires spasmodically but does not actually start. Now the magnetic strength in the main and auxiliary winding is insufficient to oppose the armature return spring and hold the pinion in full engagement. However, this is prevented by the holding winding as the current in this winding is not affected by the back-emf. Once the pinion has de-meshed and the armature has returned back, the momentum of the rotating mass tends to keep the armature rotating. This is however resisted by the ‘generator effect’ developed due to the interaction of the holding winding and the armature. This electrical reaction quickly brings the armature to rest. The pinion joins to the armature shaft through a small multi-plate clutch, which serves two functions.

(i) It slips when the torque applied to it exceeds a predetermined limiting value, so that the starter is safeguarded from damage if the engine backfires.

(ii) It disengages when the engine starts and tends to drive the pinion faster than the armature, so that the armature is prevented from damage by excessive speed.

Fig. 15.30. Circuit diagram of coaxial starter.

15.8.2.

Coaxial (Sliding Gear) Starter Motor

Similar to the axial starter motor, the coaxial starter motor moves the pinion into engagement under reduced power and when it is fully meshed only then full power is applied. The main difference lies in the method of sliding the pinion into mesh with the ring gear. Instead of the whole armature assembly moving axially, in this type a solenoid mounted coaxially with the shaft in a housing moves only the pinion for engagement.

The main details of the circuit of a coaxial starting motor are shown in Fig. 15.30. The main terminal is

connected directly to the battery and the terminal marked ‘sol’ is connected to the battery through the drivers starter switch. When this switch is operated, the two-stage solenoid is energized, which moves the pinion into mesh and also closes the first set of contacts, the second set is kept open by trip lever. During this period, a resistor limits the current to the main field, so the armature rotates slowly. Just before reaching the fully meshed position between the pinion and ring gear, a lever trips the second set of contacts. This action by-passes the resistor, and supplies full current to the main field so that the motor produces its maximum torque.

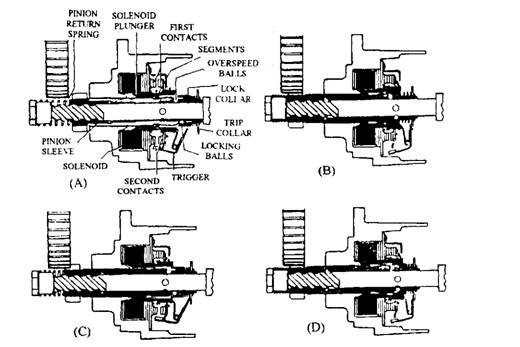

Fig. 15.31. Actions of coaxial starter.

A. At rest position. B. Cranking position.

C. Engaging position. D. Over-speed position.

The actions of one type of Lucas CAV motor are presented in Fig. 15.31. This design uses four steel balls, which lock the pinion sleeve to the shaft to avoid premature rejection of the pinion during spasmodically firing of the engine. When the engine starts and operates on it own, over-speeding of the motor is prevented by the centrifugal action of a set of steel balls placed adjacent to the locking balls. When a pre-set speed is reached, the centrifugal force on the balls moves the locking collar outward and allows the pinion to disengage. A return spring positioned at the flywheel end of the armature shaft helps pinion disengagement and holds the pinion clear of the flywheel during running of the engine.

In Bosch sliding-gear motors the main solenoid is installed at the opposite end of the motor to the pinion. This solenoid holds the pinion in full engagement position until the driver releases the starter switch. Drive from the armature to the pinion is transmitted by a multi-disc clutch. This clutch limits the torque to be transmitted and hence prevents over speeding of the motor by releasing the plates and slipping when the engine is started. Some motors have a shunt field winding, which limits the no-load speed and others use a brake winding that comes into action when the driver releases the starter switch.