25.8.

Gear Interlocking Device

Changing the gear ratio involves two separate operations, (a) Swinging the gear-lever lower end across the channel formed by the three selector

gates until the flats are aligned with the desired selector-rod gate. (6) Sliding the selected gate and rod axially and parallel to the gearbox shafts towards

the desired gear until the dog-clutch and gearwheel dog teeth mesh and engage.

It is, however, possible for the rectangular-sectioned lower lever with its semi-rounded tip to be placed or aligned between two selector gates while selecting the individual gates. In this position sliding the lever parallel to the gearbox shaft forces with gates to engage two different gears simultaneously, providing two power-flow paths. This can cause the whole gear pack to jam, so that the weakest gear teeth can smash and strip from their roots, if the vehicle is in motion. To prevent such a situation, every gearbox incorporates some sort of safety interlocking device.

25.8.1.

Plunger-and-pin Interlocking Device Three Selector Rod Systems.

This device (Fig. 25.15) uses two plungers and an interconnecting pin. The mechanism incorporates three selector rods. The central rod has a radial hole drilled through it, and the mouths of the hole are chamfered. An interconnecting pin is fitted inside this hole. The selector rods have single grooves cut on each side of this central rod facing the middle rod. Holes drilled in the gearbox casing or cover housing (between the rods) at right angles to the selector rods hold two interlocking balls or spherical-ended plungers. In the neutral gear position, each plunger rests in the groove on the outer selector rod and in the chamfered hole on the central rod.

When a gear ratio requiring involvement of one of the outer selector rods is selected, the selector rod moves one way or the other from the neutral position to engage the dog-clutch outer hub with the dog teeth of selected gear wheel. The movement of the selector rod pushes the contacting interlocking plunger with its spherical ends out of the groove and away from the rod causing the plunger end to contact the straight shank of the rod. The movement of this interlocking plunger at right angles to the selector rod is also relayed to the pin and to the other interlocking plunger, which now is partially located and locked in the groove in the third selector rod. Consequently, while the first rod is free to be shifted to and fro unrestricted, the two selector rods not in use are wedged in the neutral position by the plungers and pin.

Also, if a selected gear ratio requires the central selector rod to be shifted, both interlocking plungers are pushed out of the chamfered hole ends and outwards from the central rod as its straight shank is made to contact the plunger spherical ends. As a result the other ends of both plunges are now positioned and locked against the grooves of the outer selector rods. This again permits the movement of only one rod, while the other two rods are locked in their neutral positions.

25.8.2.

Caliper-plate Interlocking Device Three Selector Rods System.

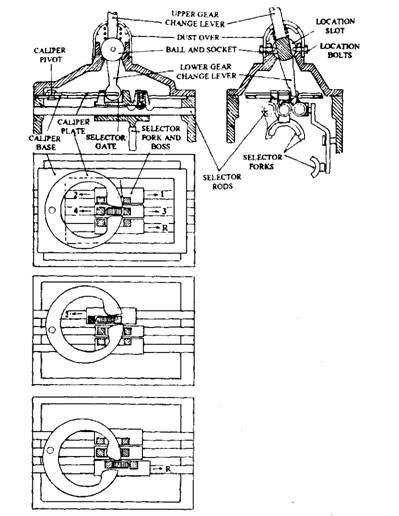

This arrangement (Fig. 25.16) uses three selector rods, held rigid at their ends in the gearbox casing or cover housing. The selector forks are free to slide along their respective selector rods through bosses, which have selector gates on top to locate and align both the gear-lever spherical end and the caliper plate (or swing plate). In the neutral position, all three selector gates remain aligned, and the gear-lever end is located in the middle gate with the ends of the caliper plate on each side of it.

The ends of the caliper plate fit across the first and third gate so that these two gates and forks are not allowed to be engaged, but the central gate can shift to and fro to obtain its respective gear ratio using the middle selector rod. To employ one of the outer gates and forks for gear selection and engagement, the gear lever is pushed over or tilted. This causes the spherical gear lever end to be in one of the outer gates, and the caliper plate to swivel so that it jams across two of the selector gates, avoiding any accidental shifting and engagement of other gear ratios.

Single Selector Rod System.

This arrangement (Figs. 25.17 and 25.18) uses only one selector rod or rail, and a selector boss and striking pin are fixed to it. Unlike the conventional three-selector-rod arrangement, the single-rod method adopts a to-and-fro movement and a rotary twisting motion for gear-ratio selection and engagement. In this layout, there are two selector-fork-and-gate bosses, which can

Fig. 25.16. Three-rod gear-selection mechanism with caliper-plate interlocking device.

slide freely on the rail, the third selector gate forms the part of the reverse relay lever. A caliper plate is situated at right angles and half-way along this rail and is pivoted and supported at one end by the gearbox housing.

For selecting a particular gear ratio, the selector rail is twisted or rotated slightly until the striking pin aligns with the required selector gear. At the same time the caliper plate is compelled to follow this movement and it just slips across the selector gates. Consequently, whatever gate the striking pin is aligned with, the other two gates have a portion of the caliper plate jamming them and so the other selector fork or the reverse relay lever is prevented from moving along the rail. For changing to another gear ratio, the selector rail is moved backwards or forwards until the striking pin is in the neutral position, so that the three gates level with each other. The rail is then rotated until it aligns with the selected gate, followed by the pin pushing one of the forks or relay levers into an engaged position.