Engine Construction

The major components of an automobile reciprocating piston engine are the

cylinder block, oil pan, cylinder head, intake manifold, exhaust manifold, crankshaft,

flywheel, camshaft, oil seals, bearings, connecting rod, piston, piston rings, valve

train etc. This chapter deals with all these components with respect to their function,

construction, design considerations, materials, trends, etc.

3.1.

Cylinder Block

The cylinder block is the portion of the engine between the cylinder head and sump (oil pan)

and is the supporting structure for the entire engine. All the engine parts are mounted on it or

in it and this holds the parts in alignment. Large diameter holes in the block-castings form the

cylinder bores required to guide the pistons. These holes are called bores as they are made by

boring. The cylinders are provided with a web or bulkhead to support the crankshaft and head

attachments. Each main bearing bulkhead supports both a cam bearing and a main bearing.

The bulkhead is well ribbed to support and distribute loads applied to it. This gives the block

structural rigidity and beam stiffness. The cylinders are surrounded by cooling passages. The

block has drilled passages for the flow of coolant and lubricating oil separately. When a curved

passage is needed, intersecting drilled holes are used. After oil holes are drilled the unneeded

open ends are capped by pipe plugs, steel balls, or cup-type soft plugs. The head, pan, and timing

cover are fixed to the block with sealed joints for eliminating leakage. Gaskets are used in the

joints to take up machining irregularities and to absorb variations due to pressure and

temperature extremities.

Within the cylinder, combustion process produces rapid and periodic rises in temperature

and pressure. These induce circumferential and longitudinal tensile stresses, which act around

the cylinder and in the direction of the cylinder axis respectively. These induced stresses are of

pulsating nature, so that the cylinder is continuously stretched and contracted while in

operation. Combustion pressure loads are carried from the head to the crankshaft bearings

through the block structure. Mounting pads or lugs on the block transfer the reaction loads

caused by the engine torque to the vehicle frame.

The cylinder head is fastened to the top surface of the block, called the block deck. The deck

has a smooth surface to seal against the head gasket. Threaded bolt holes are provided around

the cylinders to form an even holding pattern. These bolt holes go into reinforced areas within

the block that carry the load to the main bearing bulkheads.

The cylinders may be of a skirt-less design, flush with the top of the crankcase, or they may

have a skirt that extends into the crankcase. Extended skirt cylinders are used on engines with

short connecting rods. As a result a low overall engine height can be obtained since it has a

small block size for its displacement. In most skirtless cylinder designs, the cooling passages

extend nearly to the bottom of the cylinder. In skirted cylinder designs, the cooling passages are

limited to the upper portion of the cylinder.

Both spark-ignition cylinder blocks and compression-ignition cylinder blocks are similar,

but latter blocks are relatively heavier and stronger to withstand high compression ratios and

internal pressure.

3.1.1.

Types of Block

In-line Cylinders.

The in-line cylinder block assembly is available with many variations. One type uses a single

monoblock casting forming an integral cylinder block and crankcase (Fig. 3.1). Another type

uses a separate casting for cylinder head, cylinder block and crankcase (Fig. 3.2). The monoblock

cylinder block and crankcase is relatively easy to cast, is cheap to manufacture, and produces

a very stiff combined structure. This type is commonly used for small and medium engines. The

detachable bolt-on crankcase is used on some large diesel engines where an aluminium-alloy

crankcase is bolted on to a cast-iron block to minimize weight. The combined head and cylinder

block casting with a bolt-on crankcase has been used in heavy duty diesel engines to minimize

thermal distortion.

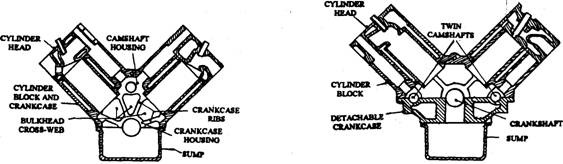

Fig. 3.1. Monoblock cylinder block and crankcase. Fig. 3.2 Cylinder block with detachable crankcase.

Horizontally Opposed Cylinders.

Horizontally opposed cylinders generally have a separate crankcase with banks of two or

three cylinders bolted on opposite sides (Fig. 3.3) or two half integral cylinder block and

crankcase banks bolted together (Fig. 3.4). There is either a central camshaft to actuate the

valve push-rods, or twin camshafts, one for each bank.

Fig. 3.3. Horizontally opposed cylinder Fig. 3.4. Horizontally opposed cylinder

with detachable crankcase. with divided crankcase.

V-banked Cylinders.

V-banked cylinders have compact and rigid arrangements and are common in engine of 2.5

liters or above. The angle between banks is generally 60 degrees for four- and six-cylinder

engines, and 90 degrees for eight-cylinder engines. An integral cylinder block and crankcase is

used with this block. In this arrangement a central camshaft actuates the valves in each cylinder

block (Fig. 3.5). However, in some heavy-duty diesel engines a separate crankcase is used with

a separate camshaft for each bank (Fig. 3.6).

Fig. 3.5. Monoblock V cylinder Fig. 3.6. ‘V cylinder block

block and crankcase. with detachable crankcase.

3.1.2.

The Coolant Passages

The coolant passages are cast in the cylinder block. These surround the cylinder walls

circumferentially and lengthwise covering approximately the full depth of the cylinders. The

coolant passages terminate near the bottom of the cylinders, where the cylinder walls merge

with the crankcase. At the top of the cylinder, the coolant passages end either at the level of the

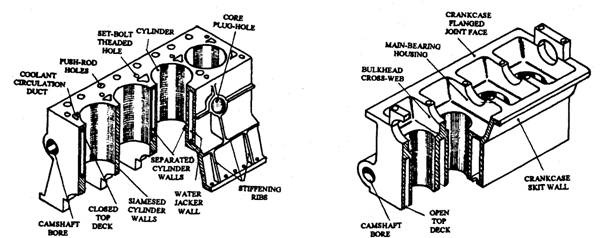

block’s joint face, called as an open deck (Fig. 3.7), or just below the block’s machine face, known

as a closed deck (Fig. 3.8). In the closed deck cylinder block, the vertical drillings, which

communicate with corresponding holes in the cylinder head, provide coolant circulation. A closed

deck has better joint reliability than an open deck. On the other hand, it is easier to cast an

open-deck cylinder block.

Fig. 3.7. Closed-deck cylinder block. Fig. 3.8. Open-deck cylinder block.

3.1.3.

The Crankcase

The crankcase supports the individual main journals and bearings of the crankshaft and

also maintains the alignment of the journal axes of rotation as they are subjected to rotary and

reciprocating inertia forces and the periodic torque impulses. A tunnel-roof construction of the

crankcase is partitioned-off by bulkhead cross-webs, which mount and support the crankshaft

main journals and bearings (Fig. 3.8). This semicircular ceiling construction with spaced-out

cross-webs offers a very stiff and relatively light crankcase structure.

Over the underslung crankshaft, the crankcase walls from a skirt, which is either separately

attached to the cylinder block’s lower deck (Fig. 3.2) or merged into it as integral casting (Fig.

3.1). The crankcase skirt may enclose the crankshaft from cylinder block to crankshaft-axis level

(Fig. 3.1). However, to provide extra rigidity the walls also extend well below the crankshaft

(Fig. 3.2). This is suitable for both high-performance and heavy-duty engines. Ribs run from the

bottom of the cylinder block diagonally towards the main-bearing housings for additional

support to the cross-webs. In some aluminium-alloy integral cylinder-blocks and crankcases,

stiffening ribs are cast longitudinally and vertically downwards on the outside walls of the block

and crankcase.

Fig. 3.9. V-type engine block. Fig. 3.10. Y-type engine block.

The crankcase walls are flanged at the bottom

to strengthen the casing and to attach the sump.

Two types of lower block designs are in use, name-

ly V-block (Fig. 3.9) and Y-block or deep block :

(Fig. 3.10). The base of V-block is close to the

crankshaft centre. This block is compact and

lightweight. The Y-block improves the stiffness of

the entire engine, which provides smooth and

quite operation, and durability.

3.1.4.

Cylinder Block Material

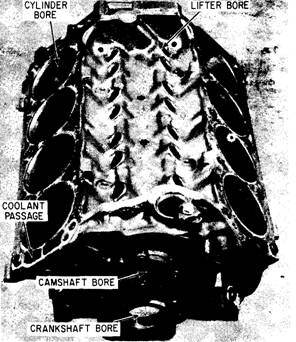

The cylinder blocks are cast in one piece from

gray iron or iron alloy containing nickel or

chromium for high strength and wear resistance.

Some cylinder blocks are cast from a silicon

aluminium alloy. The cylinder block is a compli-

cated casting. A V-8 cylinder block is illustrated

in Fig. 3.11.

When cast in a monoblock form, the cylinder

block material should have adequate strength

and rigidity in compression, bending, and torsion.

This is necessary to resist the gas pressure loads

and also for the components, which convert the

reciprocating motion of individual piston into a

single rotary motion.

The cylinder-block material should

(a) be relatively cheap,

(b) readily produce castings with good impressions,

(c) be easily machined,

id) be rigid and strong enough in both bending and torsion,

(e) have good abrasion resistance,

(f) have good corrosion resistance,

ig) have high thermal expansion,

(h) have a high thermal conductivity,

(i) retain its strength at high operating temperatures, and

(J) have a relatively low density.

Although cast iron meets most of these requirements, it has a low thermal conductivity and

is comparatively heavier. Due to these limitations, light aluminium alloys have been used as

alternative cylinder-block materials for petrol engines. Cylinder liners (refer section 3.1.5) are

optional with cast-iron blocks; but are more essential with the relatively soft light aluminium

alloy blocks, as they cannot directly withstand wear resistance. Because of the lower strength

of the aluminium alloys, the blocks are cast with thicker sections and additional support ribs,

so that their weight becomes about half of the equivalent cast-iron blocks.

Fig. 3.11. A V-8 engine block.

A typical cast iron is a gray cast iron, which contains 3.5% carbon, 2.25% silicon, 0.65%

manganese, and the balance (93.6%) iron. The carbon improves lubrication property of graphite,

the silicon controls the formation of a laminated structure, called pearlite, which has good wear

resistance, and the manganese strengthens and toughens the iron structure. A common

aluminium alloy composition is 11.5% silicon, 0.5% manganese, and 0.4% magnesium, with the

balance (87.6%) aluminium. The high silicon content in this alloy reduces expansion but

improves cast-ability, strength, and abrasion resistance, while the other two elements

strengthen the aluminium structure. While this alloy provides a good corrosion resistance, it

can absorb only moderate shock loads.

Advantages of cast iron cylinder blocks are;

(i) Good casting properties.

(ii) Free graphite helps to give good wearing properties. The cylinder bore, for example,

can be machined directly in cast iron.

(Hi) Good sound damping properties.

(iv) Tapped holes (i.e., cylinder head studs) are less easily stripped than with aluminium.

Advantages of aluminium cylinder blocks are ;

(i) Lighter in weight.

(ii) Attractive appearance.

(Hi) Easier machining during production.

(iv) Better heat dissipation.

3.1.5.

Cylinder Liner

The liner increases cylinder bore life, as this can be made of an iron suitable more for its

wearing properties than for its casting properties. A single grade of cast iron used to cast cylinder

block cannot have all the optimum individual mechanical properties such as strength, tough-

ness, hardness, and corrosion and wear resistance. Separate cylinder liners are therefore used.

These provide prolonged cylinder life, which outweighs the extra cost. The liners can be made

from lightly alloyed cast iron. They are centrifugally cast into the cylindrical sleeve, machined,

the then heat-treated to produce the optimum wear-resisting properties.

These liners are of two classes :

(i) Those, which are in direct contact with the cylinder bore walls of the cylinder block,

are known as dry liners.

(ii) Those, which are supported only at each end in the cylinder block and are elsewhere

in direct contact with the engine coolant, are known as wet liners.

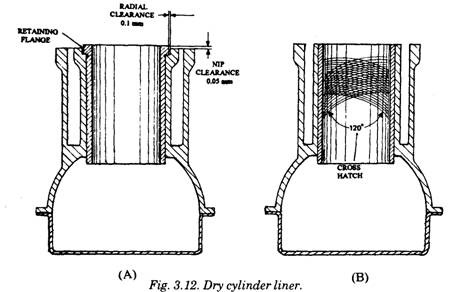

Dry Liners.

Normally dry cylinder liners (Fig. 3.12) are provided under the following circumstances :

(a) When the cylinder block is made from aluminium alloy, the cylinder bore wall should

be stronger and of much harder wear resistant material.

(b) For heavy duty operating conditions, the normal wear resistance of a cast-iron cylinder

block can be improved through sleeves with superior properties.

(c) When the cylinder block is designed with siamesed adjacent cylinder bores in order to

reduce the over all length, then only dry liners are suitable.

(d) When a cylinder block has been rebored two or three times, then dry liners are used

to restore to the original size of the cylinder bore.

(e) If both bending and torsional rigidities are of concern, a cylinder block with cast-in

coolant passages and cylinder bores fitted with dry liners is more suitable than a block

using wet liners.

The three basic fits used with dry liners are (i) cast-in fit, (ii) force (press) fit, and (Hi) slip

fit.

(i) Cast-in-fit Liner.

For using dry cylinder liners in aluminium-alloy cylinder blocks, the

outside cylindrical surface of the liner is machined to form a helical groove running from top to

bottom. The liners are generally preheated to 473 K and are then placed correctly in the

cylinder-block casting dies before casting starts. This forms a strong metallic bond between the

aluminium-alloy block and the cast-iron sleeve after solidification.

(ii) Force-fit (Press-fit) Liner.

This liner (Fig. 3.12A) is a plain cylindrical sleeve. The

liner is positioned by drawing or pushing the sleeve into the cylinder block with force. This

operation requires suitable end-plates and guides, and either a screw-and-nut draw-bar attach-

ment or a hydraulic-press set-up. Typical interference fits between the sleeve and cast-iron

cylinder block are 0.050 mm and 0.075 mm for bore diameters of 75 to 100 mm and 100 to 150

mm respectively.

(ill) Slip-fit Liner.

This liner (Fig. 3.12B) is a cylindrical sleeve, flanged at one end for

positioning and securing in its location. There is little or no contact between the liner and the

block walls. The liner is inserted by hand pressure. The flange projects above the block face by

0.05 to 0.125 mm to prevent vertical movement relative to the block while in use.

A. Plain force-fit- B. Flanged slip-fit.

Dry Liner Installation.

First the cylinder walls and their counter-bores are cleaned of

rust, carbon, and any burrs. Then diametrical distortion is checked with a micrometer or any

other similar instrument. For fitting the slip-fit liner, the matching between the flange and the

recess bore is checked by blueing the sleeve top face, upturning the sleeve, and rubbing it against

the counterbore face. The sleeve bore is checked for ovalness with a micrometer at two locations

at right angles to each other at the top, middle, and bottom of the sleeve. If the difference at any

of the locations checked exceeds 0.05 mm, the sleeve is rotated through 90 degrees in the cylinder

block and rechecked until the best position is obtained.

During boring out the cylinder block to take the sleeve or re-boring a cylinder block, the

same care for alignment, circularity, straightness, diameter, and surface finish is necessary.

The working tolerance for boring cylinder blocks is +0.0000 to 0.0125 mm.

Due to relatively thin walls the dry liners take up the contour of the finished wall profile.

‘ air pockets are formed by ridge marks from a rough single-point cutting tool, local hot spots

re produced causing distortion, rapid wear and even piston seizure.

Force-fit dry liners are normally supplied with an unfinished internal-bore diameter with

an allowance of between 0.35 mm and 0.50 mm. This allowance is removed by boring and honing

processes after the liners are installed in their respective cylinder-block bore holes. Slip-fit dry

liners may be supplied either as semi-pre-finished liners with an internal-bore allowance of

0.025 to 0.10 mm, which is removed by honing after fitting or as pre-finished liners with no

internal-bore allowance.

The liner bore surface is honed to an accuracy of 0.6 to 0.8 um centre-line (average) with a

Crosshatch angle of 120 degrees (Fig. 2.12A). This provides an optimum oil-retaining surface for

running in new piston rings and cylinder bores (ring bedding). This is required for both

gas-sealing and oil control.

Wet Liners.

Wet cylinder liners (Fig. 3.13) provide the following advantages if used in petrol engines

with aluminium alloy cylinder block having a high coefficient of expansion.

(a) Due to isolation of the bulk of the sleeve from the block, difficult expansion problems

can be resolved at one or two locations only.

(6) The use of wet liners simplifies the casting of the cylinder block. Also, castings of

suitable material can be used with an appropriate heat treatment for structural

requirements, rather than the cylinder-bore wear-resistance treatments.

(A) Fig. 3.13. Wet cylinder liners. (B)

A. Single sleeve support with open-deck. B. Double sleeve support with closed-deck.

(c) With better outside surface finish and constant wall thickness the liner improves the

thermal conductance and uniformity of cylinder cooling.

The wet liner is more rigid than a dry liner as the normal cylinder wall is eliminated in this

case. Wet liners fit into the cylinder block at the top and near the bottom, and the remaining

portion of the sleeve is unsupported. O-rings are used to prevent leakage of the coolant. Some

wet liner sleeves have a flange at the top, which sits into a recess machined in the upper deck

of the block. Sometimes a soft copper-asbestos or composite gasket is fitted between the flangf

and the block recess. To hold in position, the sleeve flange protrudes above the block’s top joir

face by 0.05 mm for bores up to 100 mm diameter and by 0.175 mm for cylinder diamete:

ranging from 100 to 150 mm.

The liner is sealed at the bottom by one or more rubber O-rings, usually fitted in grooves

(Fig. 3.13 A). Sometimes an inspection drain hole as shown in the figure is provided in the side

of the block between the seals, to check any leakage through the seals. In another wet

liner-sleeve arrangement, only the lower crankcase end of the liner is supported, which is

flanged to have contact with the corresponding machined face in the block. A flat gasket is used

between these two joint faces (Fig. 3.13B). Since the top of the liner sleeve has no side support,

it depends totally on vertical compression of the liner caused by the cylinder head and gasket

during tightening down. For correct compressive support, the liner’s top face projects above the

cylinder block’s deck by 0.03 to 0.10 mm, depending on the diameter of the cylinder bore, and

the tightening-down torque.

Wet Liner Installation.

The old gasket or/and sealing rings are removed and the portion

of the block that comes into contact with the liner is cleaned using a scraper and emery cloth.

The new liner is inserted into the block without sealing rings or gaskets. It is turned by hand

to find out if there is any tightness, which could cause distortion of the sleeve. The liner flange

must be smooth and square in the counter bore, otherwise the flange might break off while

tightening the cylinder head. Any burrs or dirt that might lift the flange is removed. The

projection of the liner flange above the block face is measured to ensure an adequate clamping

interface.

The seating rings are then fitted without overstretching or twisting them. A coating of

sealing compound may be applied and the liner sleeve is guided into place by hand, followed by

lightly tapping with a soft hammer. At this stage, the sleeve cylinder bore is checked for any

misalignment or distortion.

Liner Materials.

Some commonly used liner materials are nitrided steels, nitrided cast irons, and heat treated

chromium and other alloy cast irons. The wear resistance of these metals is at least 50% more

than the cylinder block material. The typical specification of liner material is :

Iron 93.92 to 92.22%

Carbon 3 to 3.5%

Silicon 1.8 to 2.4%

Manganese 0.5 to 0.8%

Phosphorous 0.4 to 0.7%

Sulphur 0.08%)

Chromium 0.3%

3.1.6.

Gaskets

Gaskets or static seals are used between attaching engine parts to seal the joints for

preventing either internal or external leakage. A gasket must withstand the high pressure and

temperature of the engine. Therefore, the gasket

(i) must be impermeable to the fluids in contact,

(ii) must conform to any existing surface imperfections,

(Hi) must be resilient to maintain sealing pressure, even when the joints are slightly

loosened as a result of temperature changes or vibration,

(iv) must be resistant to all expected changes in its environment due to temperature,

pressure variations, and age, and

(v) must be stable under compression conditions, avoiding excessive setting.

The essential considerations of a gasket are

(a) adequate shear and tensile strengths, particularly for use with narrow sections,

(b) adequate provision for the cooling of the mating surfaces specifically the cylinder head

and for minimizing the effect of differential thermal expansion,

(c) maintenance of a gasket-thickness tolerance, and

(d) a gasket of simple construction, easy to assemble, and not readily damaged.

The gasket thickness and hardness must be chosen to match the degree of unevenness of

either joint face due to large tolerances, distortion, surface roughness, or other factors such as

lack of uniformity of bolt or stud loading. The following gaskets are commonly used in automobile

engines.

(a) Copper-asbestos gasket.

(b) Steel-asbestos gasket.

(c) Steel-asbestos-copper gasket.

(d) Single steel ridged or corrugated gasket.

(e) Stainless steel gasket.

(f) Asbestos-coated steel sheet with separate steel beading around bore.

(g) Laminated steel and graphitized asbestos sheet with formed steel bore bead.

(h) Asbestos impregnated rubber bonded with reinforced ferrule bead.

(i) Asbestos/steel wire-reinforced tissue.

The material used for gaskets depends on the sealing requirement and cost. Cork, one of

the oldest gasket materials, has limited use only to lightly loaded joints having uneven surfaces

such as rocker covers and oil pans. Aluminium coatings on cork gaskets help reduce heat

deterioration. In some cases cork gaskets are rubber coated. Cork gaskets are often replaced by

gaskets made of fibers such as cellulose, asbestos, or a mixture of two. Gasket fibers are bonded

together with a binder, and the binder is impermeable to oil in some cases and other cases it

swells on contact with oil, depending upon the use. Fiber gaskets require a better parting surface

smoothness than is needed by cork gaskets.

Molded oil-resistant synthetic rubber is often used where the sealing requirements dictate

special seal designs such as oil pan corner joints and intake manifold ends. A new approach to

gaskets is a plastic gasket material in a tube used in place of paper and fiber-based gaskets.

Fig. 3.14. Head gasket with a fire ring.

Sealing of the cylinder head at

the block parting surface is one of the

most difficult sealing jobs. Earlier

head gaskets were copper-coated as-

bestos. As engine design improved,

copper on the gaskets was replaced

by steel to withstand the higher

pressures and temperatures. Steel

rings, called fire rings, were applied

to the gaskets around the cylinder

openings to seal the combustion

chambers (Fig. 3.14).

A more recent head gasket

development uses a thin steel core

with a thin coating of asbestos rolled

on the outside. This provides the gas-

ket the desired resilient properties

needed to withstand the head and

block temperature changes and the

pressure variations within each

cycle. Most head gaskets must be

installed in a specified direction because the gasket is often used to help control engine coolant

flow. When this is required the gasket is marked top or front. Head gasket types are shown in

Fig. 3.15A,Band C.

Timing cover gaskets are usually made of thin fiber or paper. Cork, fiber and synthetic

rubber are used in different parts of the oil pan. The intake manifold uses embossed steel or

reinforced fiber gaskets. Cork or synthetic rubber sections are used on the lifter valley cover

portion of the intake manifold. After use, a gasket loses most of its sealing properties. It is

common practice to use a new gasket each time a part is assembled. Often, the gaskets are

coated with a special varnish, which

melts and seals all the smaller inter-

sticks between the meeting surfaces

when the engine warms up.

3.1.7.

Cylinder Block Attachments

A number of parts are attached to

the engine to enclose it and to adapt it

to the vehicle. These include covers,

housings, and mounts.

Bell Housings.

A bell housing enclosing the

flywheel and clutch or torque con-

verter is attached to the rear of the

cylinder block. It is positioned with

dowel pins for alignment. Offset

dowels and shims between the block

and bell housing may be used to align

the bell housing in standard transmis-

sion applications, so that the clutch shaft matches the pilot bearing. Alignment of the automatic

transmission is simplified by using a flex plate transmission drive. Most automatic transmission

cases from the bell housing, while standard transmission have separate bell housings with cluth

lever attachments. Aluminium bell housings are normally used in passenger cars to minimize

weight.

Fig. 3.15. Types of head gaskets.

A. With metal outside the asbestos.

B. Steel embossed.

C. Steel core with outside coating of asbestos.

Timing Covers.

The simplest timing covers are made of stamped steel or cast steel (Fig. 3.16A and B) and

attached with cap screws. Its only purpose is to protect the gears from foreign objects and to

keep the engine oil in. A cast cover also tends to muffle the timing drive noise. Some timing

covers are die-cast. The die-cast process produces an almost finished cover at extra tooling cost,

which balances the savings made in machining costs. In some designs the timing cover is made

more complicated (Fig. 3.16C) by including the oil pump and distribution drive along with the

fuel pump and water pump. With this type of cover, the block contains no accessory drives.

Fig. 3.16. Timing covers.

A. Stamped steel- B. Cast steel.

C. Cast with fuel pump, water pump, oil pump, and distributor attachments.

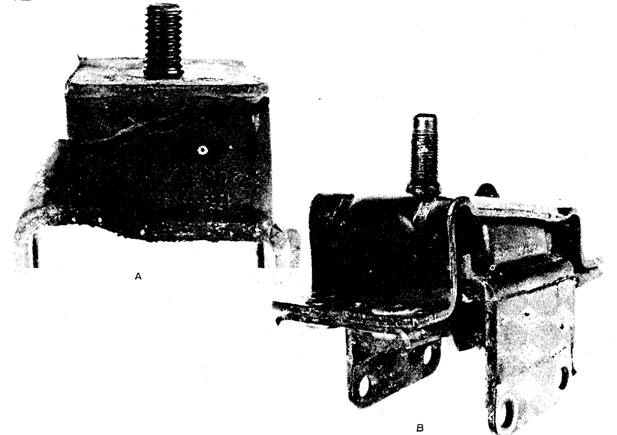

Engine Mount.

Engines are mounted on the chassis through rubber insulators. The engine mounts are

positioned close to vibration nodes, which are points of minimum vibra tion. The rubber used

in engine mounts is especially compounded to absorb vibrations, characteristic to each specific

engine model. The mounts are usually located about half way back on each side of the block.

The latest mounts (Fig. 3.17B) hold the engine even if the damper rubber breaks, in contrast to

earlier mounts (Fig. 3.17A).

Fig. 3.17. Engine mounts.

A. Old style.

B. New style.