Wrenches are probably the most basic tools for auto repair. You need a couple of different kinds in different sizes. There are several basic types of wrenches, some for very specialized purposes, but the following sections cover the kinds you need for most jobs. Look for sets made by well-known toolmakers, and try to buy them on sale. (For more pointers on buying tools, see the beginning of this chapter.)

The turning of the screw

If you find yourself confronted with a screw that’s difficult to start unscrewing, try giving the screw a slight twist in the opposite direction (clockwise), as though you were trying to tighten it. Then loosen it (counterclockwise). If this trick doesn’t work, tap the screwdriver on the head with a hammui, which may loosun the screw a bit. If strong-arm tactics aren’t getting

you anywhere, you can try squirting the troublemaker with penetrating oil. (Don’t use penetrating oil on a running engine or on any really hot areas, because it could ignite.) Remember to keep your temper with difficult screws; otherwise, you risk stripping the threads and turning a fairly simple job of replacing what you’ve loosened into a hair-puller.

Most wrenches are available in both standard — also known as SAE (Society of Automotive Engineers) — and metric measurements. You must know which system of measurement your engine is based on. Originally, most foreign vehicles (except British ones, which had their own thread standard) were based on the metric system, while domestic engines used SAE standards based on fractions of an inch. Today, most American vehicles have a mix of SAE and metric nuts and bolts. Foreign cars or foreign components used on American cars (a practice that’s becoming quite common) use metric nuts and bolts — even the inch-based British. Check your owner’s manual or ask your dealer to see whether your vehicle requires metric or standard SAE tools before you buy anything.

Combination Wrenches

When shopping for wrenches, you’ll come across open-end wrenches and box-end wrenches, but the very best kind to get are combination wrenches, which have an open end and a closed end on each wrench (see Figure 2-4). These wrenches come in sets of several sizes, and each wrench is made to fit a nut of a specific size, whichever end you use. See the sidebar “How to use a combination wrench.”

Figure 2-4:

Combination wrenches, with one open end and one boxed end, are your best bet.

Offset Wrenches

Some combination wrenches are sort of S-shaped. Called offset wrenches, these are good for working in hard-to-reach spots. You may want to add a couple to your tool kit.

The most useful offset wrench is the distributor wrench, shown in Figure 2-5, which you use to adjust your car’s timing. (You need this tool only if your car has a non-electronic ignition system.) Be sure to get one to fit the distributor hold-down clamp on your vehicle.

Figure 2-5: An offset distributor wrench is probably the most useful offset wrench.

Ignition Wrenches

Ignition wrenches (see Figure 2-6) are simply sets of combination wrenches in very small sizes for ignition work. You can get a set for a couple of dollars.

Figure 2-6:

Use ignition wrenches for ignition work.

How to use a combination wrench

Here are a few tips foi usinq a combination wrench:

To use the open end of a wiench most effectively, place it around the nut you want to lemovi! jnd then move the wiench to the right so that the nut moves in a counterclockwise direction. If the nut sticks, give it a squirt of penetrating oil or a tap on the head with a hammer

You can use your free hand to keep the wrench down ovei the nut. This gives you some contiol and prevents the wrench from flying off the nut.

When you move the wrench as far as it can go, you lossen the nut 15 degrees. (That’s why the slot is at an angle.) By simply turning the wrench over so that the other surf jr.c of the same end is around the nut, you can move the nut another 15 degrees without having to place the wrench at a different angle.

Always use the proper size wrench. If the wrench that you use is too big, it can slip and round off the edges of the nut, which makes the nut harder to tighten later on. It can also round off the inside edges of the wrench, with the same results. (Of couise, a wrench that is too small won’t fit over the nut.)

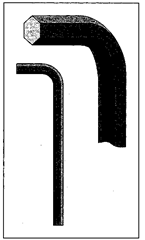

Alien (or hex) Wrenches

Some of the screws or fastenings on your vehicle may have odd-shaped holes in the centers of their heads that require special Allen wrenches — L-shaped rods that fit into the holes (see Figure 2-7). If the center hole is hexagonal, the wrench you need is sometimes called a hex wrench. You can buy a set of assorted-sized Allen wrenches for under $15.

Figure 2-7: Allen wrenches.

Socket Wrenches

A good set of socket wrenches, shown in Figure 2-8, can really make the difference between enjoying your work and killing yourself over it. Socket wrenches come in sets for a wide variety of prices, depending on quality and how many there are in the set. Sets can include either a mix of SAE and metric sockets, all SAE, or all metric pieces. Unless you’ve decided to become a mechanic, you can buy an inexpensive set of basic socket wrenches suitable for your vehicle for less than $25.

Figure 2-8:

A socket wrench set.

Your set of socket wrenches should contain the following basic items:

A variety of %-inch or %-inch drive heads or sockets: The #-inch, %-inch, and %-inch sockets are the ones you’ll use the most, unless you need a metric set. The metric sizes most often used are 10,11,12,13, and 14 mm.

The word drive refers to the size of the square hole in each socket where it attaches to the ratchet handle. It’s easy to remember that the smaller the drive, the smaller the job you use it for. A M-inch drive is for tiny areas; %-inch drive is for the next range of sizes, typically up to SAE % or 18 mm metric; &-inch drive is for up to SAE IX, or up to 25 mm; and other drives up to 2 inches are for really big jobs (you won’t need one of these monsters). You can use adapters to convert sockets of one drive to fit handles of another drive.

A spark plug socket: This is the large socket with a soft lining to hold the spark plug securely without damaging its soft jacket when you remove and insert it, or when you drop it on the floor by mistake. Spark plugs come in two sizes, so make sure to get the size that fits the spark plugs in your car. Your owner’s manual may note the spark plug size.

At least one ratchet handle, to which you can fit any of the sockets:

Most sets have two or three handles with at least one adapter. You may want to add additional adapters to extend the handle to different sizes and adapt it to different drives. Figure 2-9 shows the wide variety of sockets, handles, and adapters available.

A -Adapter B, C, E -Extension bars

D -Sliding T handle

F -Deep 6-point socket

G -Deep 12-point socket

H -Spark plug socket

I -Speeder handle

J -Rachet adapter

K -Regular 6-point socket

L -Regular 12-point socket

M -Hollow screw socket bit

N -Universal 12-point socket

0 -Flex handle

P -Flex head rachet

Q -Reversible rachet

R -Universal joint

Figure 2-9:

The parts of a socket wrench: adapters, ratchet handles, and extenders.

A flex-head handle:

Although not strictly necessary, a flex-head handle is very useful. It enables you to hold the ratchet handle at any angle when working in tight places — and engines are full of tight places!

Socket extenders:

These indispensable items help you get your socket head way down into the bowels of your engine compartment to reach those almost-unreachable nuts and bolts.

The way to tell a good socket wrench set is to look at the number of teeth in the ratchet handle. Most have 20 to 30 teeth. The really good ones have up to 60 teeth. The more teeth the handle has, the better it can fit into tight places. This is because you have to move the handle only a few degrees to turn the nut as much as a cheaper handle would in many degrees. In other words, a ratchet handle with 24 teeth must be moved 15 degrees to reach its limit. A handle with 60 teeth has to be moved only 6 degrees to turn a nut as far. You can find instructions for using a socket wrench in the section called “Removing spark plugs” in Chapter 12.

Torque Wrenches

A torque wrench, shown in Figure 2-10, is designed to tighten a nut, bolt, or screw to an exact degree. A torque wrench is extremely handy because, until you become familiar with a job, you always run the risk of undertightening or overtightening things.

If you’re replacing a spark plug and you don’t tighten it enough, it will work itself loose and fail to deliver a spark. If you overtighten a spark plug, you can strip the threads or crack the plug. Similarly, parts that have gaskets can leak if the bolts that hold them aren’t tightened enough. But if you overtighten the same bolts, the gaskets will be crushed, causing the fluid to leak anyway.

Most really good torque wrenches are expensive, but a cheaper one is good enough to serve your purposes. If you’d rather not spend the money until you’re sure that you’re really going to like working on your car, borrow a torque wrench just to get the feel of how tight a nut, bolt, or other part should be. Or you can just forget the whole thing. I’ve never used a torque wrench; my set of socket wrenches accomplished everything quite well for the work in this topic. If you are planning to buy a torque wrench, get one with a slim profile, because torque wrenches are bulky anyway and often don’t fit into tight places.

Figure 2-10:

Dial torque wrench Heft) and deflecting beam torque wrench.

If you use a torque wrench, keep the following in mind:

Grip a torque wrench well down the shaft (not up close to the dial) and operate it smoothly. !

Tighten a series of nuts or bolts in a sequence that distributes the pressure evenly, instead of in strict clockwise or counterclockwise order.

When tightening a series of bolts, tighten them all just until they’re snug. Then go back and tighten them all a bit more. Then go back and tighten them all the way to the torque specifications. Doing so ensures that the entire part you’re tightening is under even pressure, prevents leaky gaskets, and increases the life of the bolt and the part. This and the preceding tips are good to follow when you’re using any kind of wrench to tighten anything.

Before using a torque wrench, make sure that the nut or bolt turns freely so that the torque wrench gets a true reading of the proper nut tightness. You can use a lubricant such as WD-40 on the threads and run the nut up and down a few times to free it before using the torque wrench on it.

Adjustable Wrenches

An adjustable wrench, sometimes called a monkey wrench, is a useful addition to your toolbox. (See Figure 2-11.) You probably already have one in the house. You can adjust the jaws to fit a variety of nuts and bolts simply by turning the wheel. I like the very small and medium sizes because they fit into tight spaces easily.

Figure 2-11:

An adjustable wrench has many uses.

You may associate hammers solely with carpentry, but they’re useful in automotive work as well. In auto repair, you use a hammer to “sweet talk” something loose (like a nut or bolt that’s on too tight). You don’t use a hammer to whack the tar out of your engine.

Make sure that you use the right kind of hammer. You should have a ball-peen hammer (see Figure 2-12). A carpenter’s hammer (or claw hammer) isn’t really designed for auto repair.

Figure 2-12:

Use a ball-peen hammer, rather than a claw hammer, for car repair.

If all you have is a carpenter’s hammer and you don’t want to buy another one, you can probably make do with it. Just be sure that the hammer you use doesn’t have a loose head. If the shaft isn’t securely sunk into the head, the head can fly off and damage your car, you, or an innocent bystander. Claw hammers can also be dangerous because a hard, solid impact can cause the claws to break off, with dismal results.