Geoscience Reference

In-Depth Information

•

To obtain N* values, SPT refusal values are required in both seating and test drive

(refer Chapter 4). Note that some procedures recommend refusal in the seating

drive only - but this is insufficient data.

•

Higher values of allowable bearing capacity are likely with more detailed testing

from rock core samples.

•

The bearing capacity of some non durable rocks can decrease when its overburden

is removed and the rock is exposed and subject to weathering and/or moisture

changes.

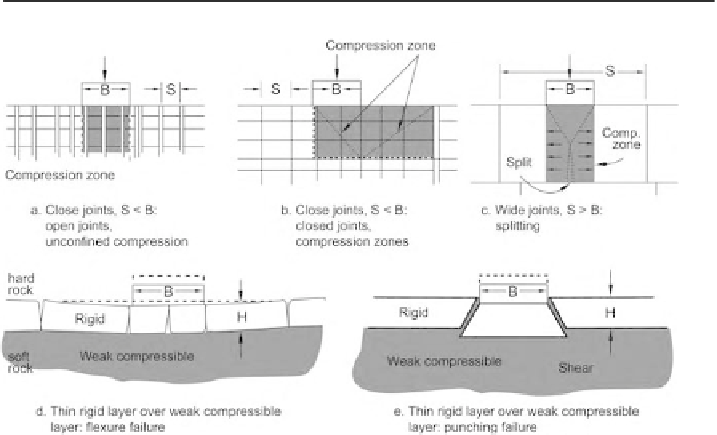

22.3 Bearing capacity modes of failure

•

The mode of failure depends on the joint spacing in relation to the footing size.

•

Driven Piles therefore have a higher bearing capacity due to its relative size to joint

spacing.

•

Bored Piles (Drilled Shafts) have a lower bearing capacity than driven piles due to

its relative size.

Table 22.3

Failures modes in rock (after Sowers, 1979).

Relation of joint spacing (S) to

Joints

Orientation

Failure mode

footing width (B)

S

B

Open

Vertical to sub-

Uniaxial compression

<

S

<

B

Closed

vertical

Shear zone

S

B

Wide

90

◦

to

70

◦

Splitting

>

S

>

B. Thick rigid layer

N/A

Horizontal to

Flexure

over weaker layer

sub-horizontal

S

<

B. Thin rigid layer

N/A

Punching

over weaker layer

Figure 22.1

Bearing capacity failures modes (Sowers, 1979).

Search WWH ::

Custom Search