Geoscience Reference

In-Depth Information

Table 1.

(A) Case study I-a. Summary of the performed CFD simulations of Run 15 in the laboratory experimental study.

(B) Case Study I-b-c. Summary of the performed CFD simulations of Run 36 in the laboratory experimental study; one grain

size. The irst ive rows refer to a mono disperse mixture d50 = 50 µm; the last four rows to a bi-disperse mixture d50 = 50 µm

and d50 = 144 µm).

A

Bedload

coefficient

Entrainment

coefficient

Turbulence Mixing

Length (m)

Angle of

Repose (deg)

Roughness (mm)

Run15a

8

0.018

0.0025

25

0.165

Run15b

8

0.018

0.0025

25

0

Run15c

0

0.018

0.0025

25

0.165

Run15d

4

0.018

0.0015

25

0.165

Run15e

12

0.018

0.0015

25

0.165

Run15f

8

0.01

0.0025

25

0.165

Run15g

8

0.025

0.0015

25

0.165

Run15h

8

0.018

0.0015

25

0.165

Run15i

8

0.018

dynamically

computed

25

0.165

Run15j

8

0.018

0.0025

12

0.165

B

Bedload

coefficient

Entrainment

coefficient

Turbulence mixing

length (m)

Angle of

repose (deg)

Roughness (mm)

36a

8

0.018

0.002

25

0.144

36b

5

0.018

0.0025

25

0.144

36c

1

0.018

0.003

25

0.144

36d

0.2

0.018

0.0025

25

0.144

36e

0.01

0.018

0.0025

25

0.144

36

2 grains a

8

0.018

0.001

25

0.144

36

2 grains b

8

0.018

0.0015

25

0.144

36

2 grains c

8

0.018

0.002

25

0.144

36

2 grains d

8

0.018

0.001

25

0.25

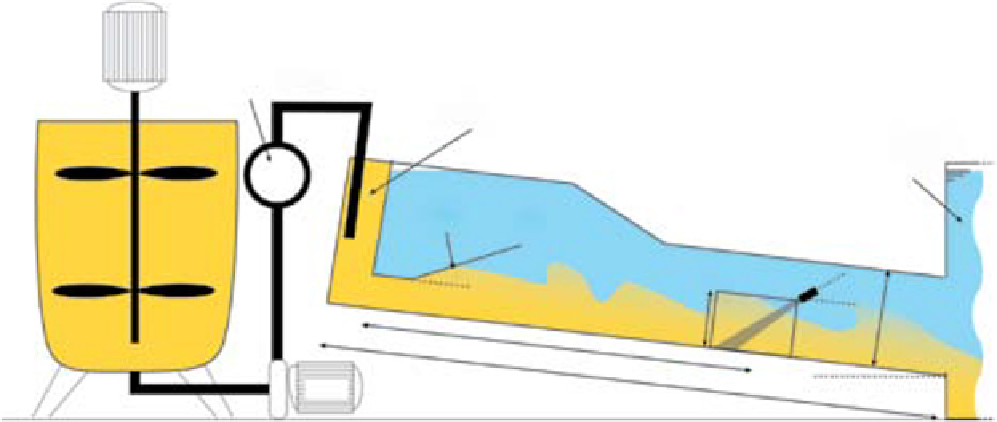

Discharge meter

Inlet chamber

Free expansion tank

3

×

2

×

1.8 m

D

Mixing

tank

Gradual expansion

1 m

3

25°

UVP-probe

45°

0.5 m

Pump

Fig. 1.

Sketch for the experimental set-up used for the high concentration turbidity currents experiments.

Search WWH ::

Custom Search