Geoscience Reference

In-Depth Information

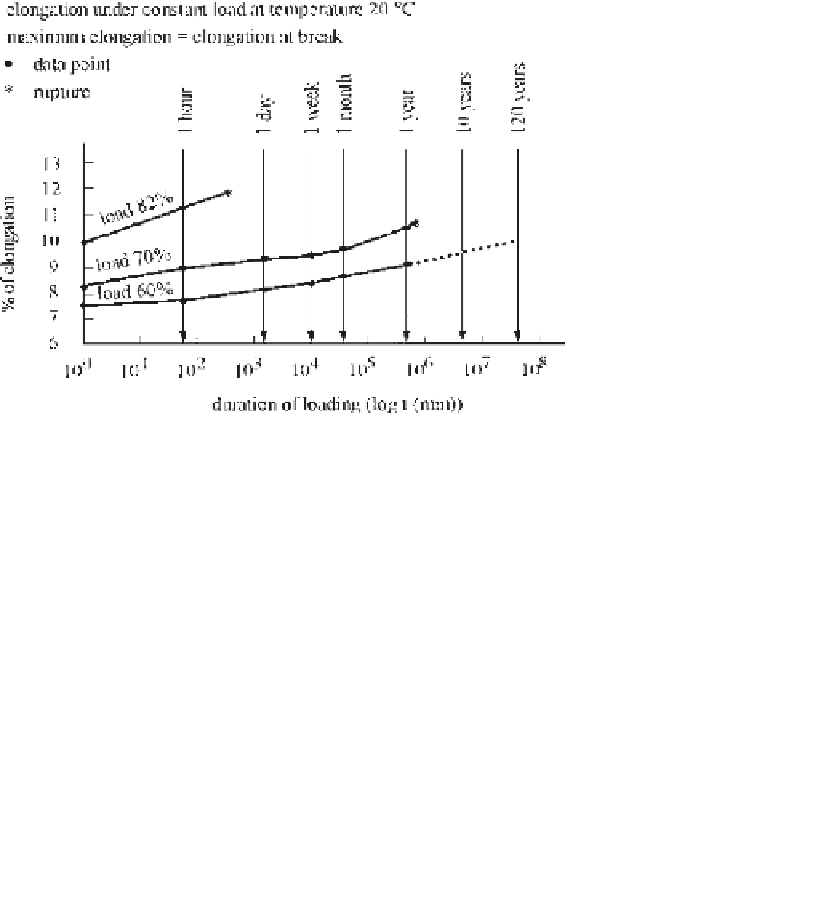

Figure 3

Typical creep graphs, Fortrac.

where

T

d

is the design strength.

T

c

is the characteristic strength above which the material fails in tension

from peak loading during the design life of the structure.

f

m

is a material factor f

m

¼

f

m1

·f

m2

;

where f

m1

¼

f

m11

·f

m12

and f

m2

¼

f

m21

·f

m22

:

The various factors f

mxx

are described in the BS 8006 and cover factors for

manufacture/control values, extrapolation of test data, susceptibility to damage,

and environment. The values of the above parameters differ for flexible and stiff

grids. Various loads factors f are used in the design to complete the ultimate

limit state design. This method complies with the approach followed in

Eurocode 7 for geotechnical designs. P

char

[t, T ]orT

c

for HDPE grids is derived

from a creep deformation limit of 10% during a design life (Jewell and

Greenwood, 1988). In the case of polyester (PET) grids, this value is obtained

from stress-rupture data produced by tests on yarns running more than 10 years

and tests on actual products running for more than 9 years now. All these data

are summarized in one stress-rupture graph, which is normalized as a

percentage of the short-term ultimate tensile strength, to give the so-called

stress-rupture graph,

in which a 95% confidence limit

indicates the

characteristic levels (Voskamp, 1990).

Search WWH ::

Custom Search