Geoscience Reference

In-Depth Information

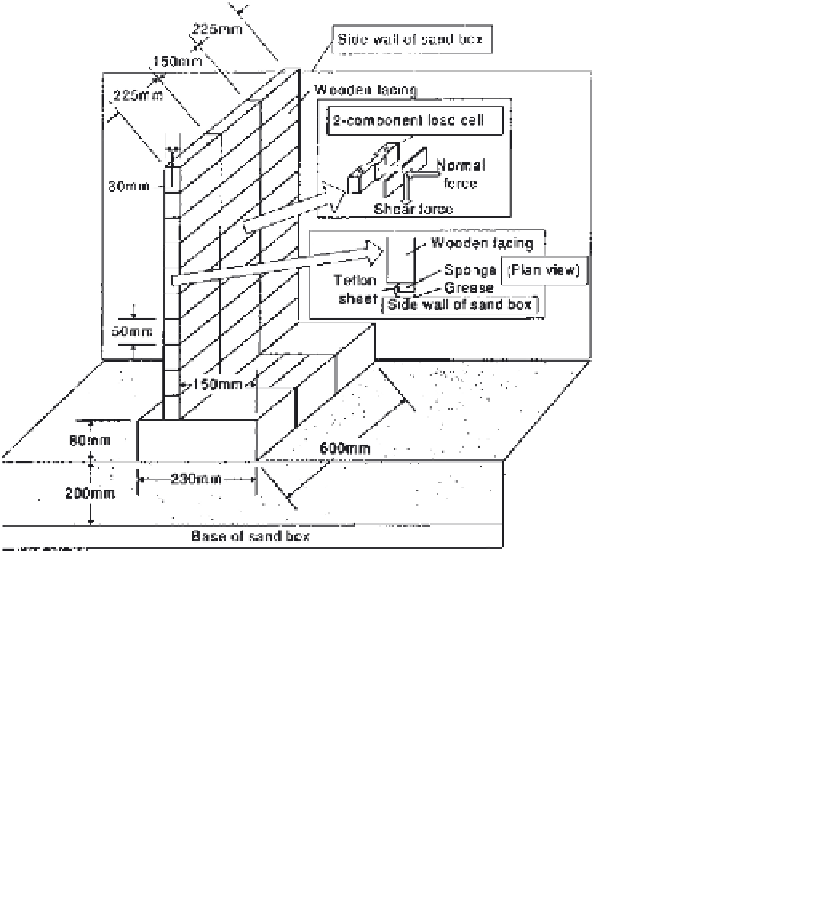

Figure 2

Details of typical wall model.

horizontal L-shapemetals. To reinforce the base, metal plates having a thickness of

10mmwere inserted at its middle level. The surfaces of the facing and base parts in

contact with the backfill and subsoil layers were made rough by gluing sandpaper.

For the reinforced soil RW models, a grid of phosphor-bronze strips was

used as the model reinforcement. To form a model grid reinforcement layer, strips

having a thickness of 0.1 mm and a width of 3mmwere soldered to each other at an

interval of 50 mm in the longitudinal direction, in parallel with the side wall, and

100mm in the transverse direction, in parallel with the facing, as shown in

Fig. 3

.

To effectively mobilize friction between the reinforcement and the backfill, sand

particles were glued on the surface of the strips. The details of the model wall and

reinforcement configurations are described in Koseki et al. (1998a).

4 BACKFILL AND SUBSOIL MATERIAL

Air-dried Toyoura sand, having e

max

¼

0.977, e

min

¼

0.605, G

s

¼

2.64,

D

10

¼

0.11mm, and D

50

¼

0.23mm, was used to form the backfill and subsoil

Search WWH ::

Custom Search