Geoscience Reference

In-Depth Information

of the GRS walls were conducted under a quality assurance system. This means

that there were a number of check/hold points in both the design and construction

processes. The success of this project under such a demanding contractual

environment attested to the effectiveness of GRS walls. The tallest GRS wall for

the M2 project was 18.71 m. It was founded directly on sandstone bedrock, but

the possible presence of weak horizontal bedding joints was considered in the

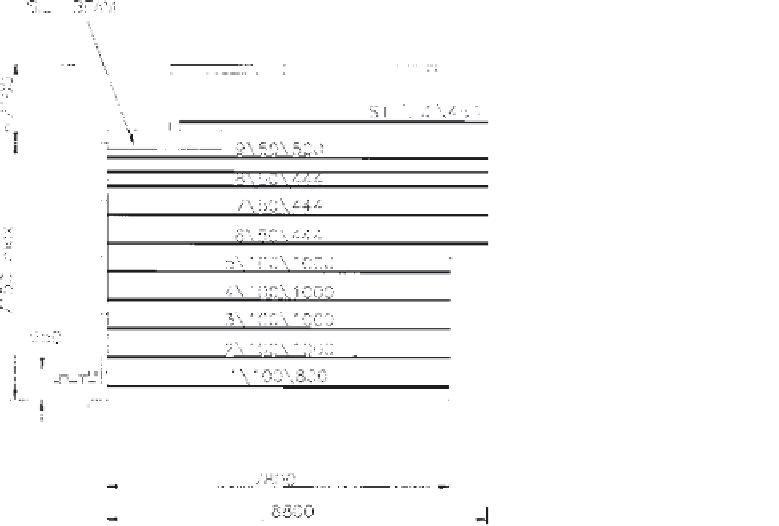

design. This wall section is a stepped wall (see

Fig. 15

)

constructed from three

different grades of reinforcing straps and utilizing six different horizontal

spacings. A number of abutment walls that directly support bridge decks were

constructed. One such wall section is shown in Fig. 16. The sill beam is about

25.7m in length. The design vertical loadings from the bridge deck are 8400 kN

and 2460 kN for dead and live load respectively. The top 2 to 2.5m of in-situ

material below the foundation level were replaced by crushed sandstone

compacted to a target dry density of 18.5 kN/m

3

. This layer is underlain by

sandstone bedrock. An inverted tee-shape sill beam contributed to minimizing

the end rotation of the bridge deck (due to the tilt of the sill beam). It is important

to backfill behind and against the sill beam before placement of bridge beams.

Figure 16

GRS wall supporting bridge deck.

Search WWH ::

Custom Search