Geoscience Reference

In-Depth Information

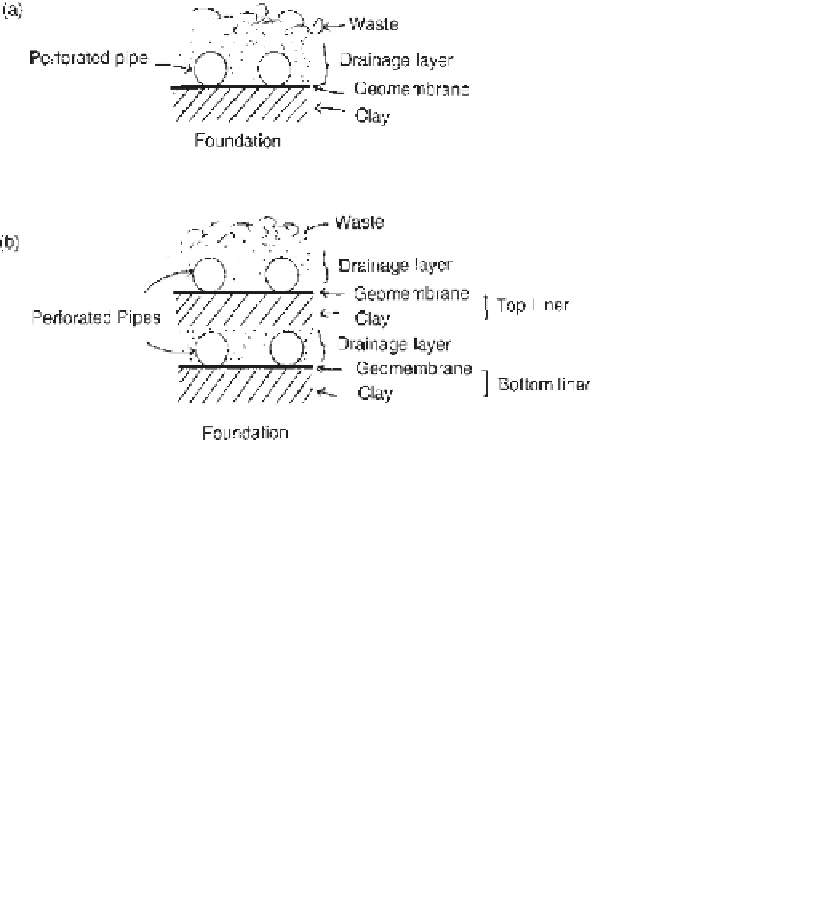

Figure 6

Geosynthetic applications in waste containment: (a) single composite liner;

(b) double composite liner.

Because of the impermeability requirement of the geomembrane liner,

permeation and leakage due to defects, such as pinholes, seams, cracks,

punctures, and tears, are evaluated. Theoretical and empirical equations are

available to determine the amount of leakage (which depends on the type of

linear), field soil conditions, and leachate head (which is typically kept below

30 cm). It is well known that the use of a double composite liner minimizes the

leakage rate.

Waste decomposition generates a significant amount of gas, such as

methane and carbon dioxide, in municipal solid waste landfill. Methane is lighter

than air; it rises to the top of the waste and is trapped under the cover. The gas

may uplift the cover and damage the geomembrane. Thus a proper gas collection

and removal system is required. Also, because of the large settlement

encountered in the landfill, a provision for differential settlement has to be

made in the design of the cover system.

The long-term exposure of the geomembrane to heat induces wrinkles/-

waves and leads to evaporation of moisture from the underlying clay liner.

Subsequent cooling allows the condensate to drip back to the clay. Along the

slope, the desiccation of clay liner occurs at the top, whereas the condensate tends

to accumulate at the toe, especially along the path of wrinkles, giving rise to wet

Search WWH ::

Custom Search