Geoscience Reference

In-Depth Information

Table 3

Characteristics of the Fill Materials

c

0

(kPa)

f

0

(deg)

D

10

(mm)

D

50

(mm)

g

(kN/m

3

)

Structure

Type of soil

G

C

u

Sau´pe

Silty sand

2.66

0.001

0.20

280

19.9

31.8

36.1

Suba´ma

Clayey sand

2.64

0.0002

0.21

1350

19.8

29.2

37.8

B´

Clayey sand

2.66

0.0001

0.25

3000

20.2

16.3

41.1

Mucambo

Sand

NA

NA

NA

NA

18.5

0

29.9

Itarir´

Sand

NA

NA

NA

NA

20.1

4.6

28.1

NA

specific

weight, effective cohesion, and effective friction angle at optimum moisture content, respectively.

G

¼

specific gravity of the soil particles, D

10

and D

50

¼

particle diameters corresponding to 10% and

50% passing, respectively, C

u

¼

coefficient of uniformity (

¼

D

60

/D

10

).

¼

value not available. c

0

and f

0

obtained from drained direct shear tests. g, c

0

, and f

0

¼

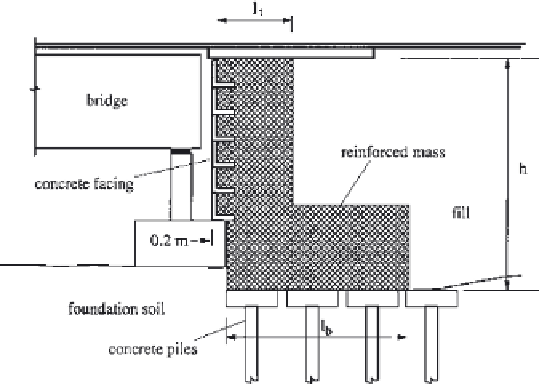

a square pattern), as shown in

Fig. 6.

The rest of the embankment was built on

the same type of piles and caps (1

0.3m) with a layer of geotextile on top

(Fig. 6). The soil used in the embankment was a fine sand (Table 3). The

foundation soil of this wall is composed by a 2-m-thick layer of clayey sand

over a soft organic clay layer with undrained strength typically varying between

also employed as reinforcement for this structure. The spacing between

geotextile layers used was equal to 0.3 m and the reinforcement length was

equal to 3.25m.

£

1

£

Figure 4

Schematic cross section of the Bu River reinforced abutment.

Search WWH ::

Custom Search