Geoscience Reference

In-Depth Information

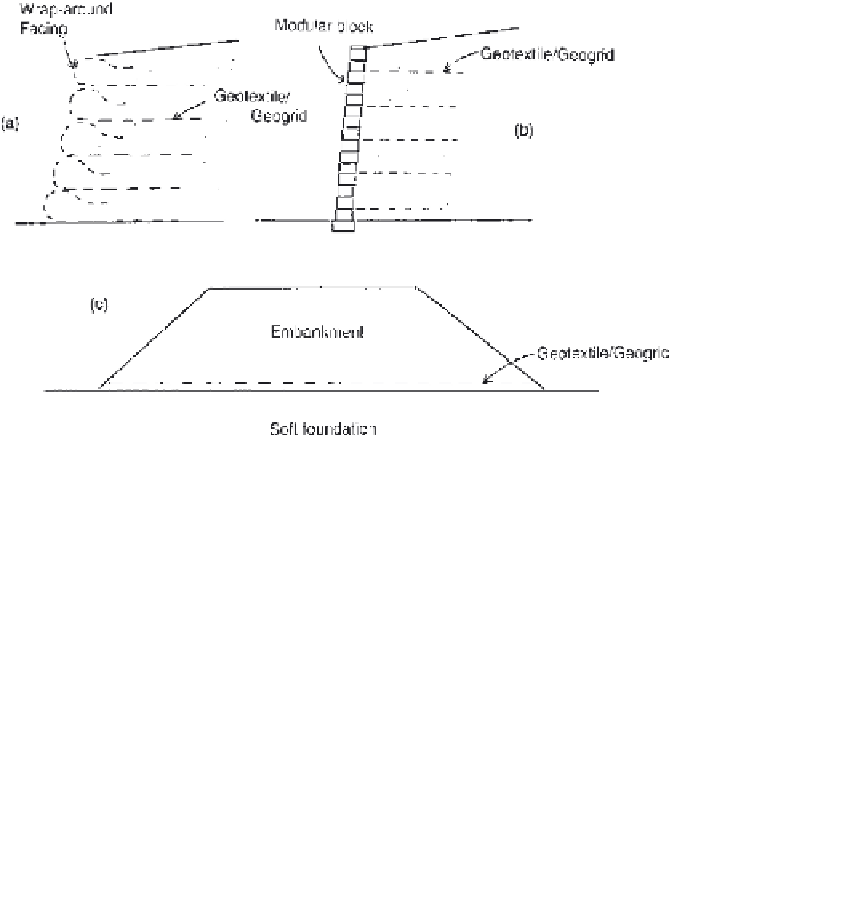

Figure 1

Geosynthetics in soil reinforcement: (a) wraparound wall; (b) modular-block

wall; (c) embankment over soft foundation.

applied considering possible strength reduction of geotextiles by installation

damage, creep, chemical and biological actions. Geotextiles may degrade by

exposure to ultraviolet rays, high temperature, oxidation, and hydrolysis (when

the environment is highly alkaline), but the effect is minimized when buried in

soils.

The frictional behavior of a geotextile with site-specific soil must be

determined by direct shear tests. Although the ASTM standard specifies a direct

shear box with dimensions of 30 cm by 30 cm, the box with a plane area of 10 cm

by 10 cm would be adequate for geotextiles. Pullout tests have been proposed in

the last few decades for determining the anchorage capacity of geosynthetics;

such tests are not relevant in determining the design parameters because they are

subject to scale and boundary effects.

For embankments and dikes constructed over a soft foundation that lacks

bearing capacity and global stability, a layer or more of geotextile is laid at the

base of the embankment. Vertical wick drains of geosynthetic composites or sand

drains may be used to accelerate consolidation of the soft foundation. Geotextiles

have also been used in conjunction with the underwater sand capping of

contaminated submarine sediments. In these applications, the seam strength may

dominate the design.

Search WWH ::

Custom Search