Geoscience Reference

In-Depth Information

limited by grain-boundary diffusion in solid-state

is the predominant deformation mechanism of

the ''dry'' silicate mantle. However, deformation

of rock wetted by solvent occurs by a pressure-

solution creep, which is limited by silicate dif-

fusion in the liquid (Weyl, 1959). The principle

of this mechanism is as follows: stress concentra-

tion at the grain contacts causes local dissolution,

diffusion of the dissolved material out of the in-

terface, and deposition at the less stressed faces of

the grains. Since the diffusion in the liquid is sev-

eral orders of magnitude faster than that in solid,

the pressure-solution creep will be much faster

than diffusion creep. The viscosity of wetted rock

is given by:

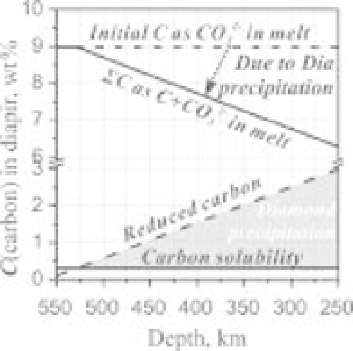

than 250 km, and is reduced to immobile diamond

or carbide since the mantle redox conditions cor-

respond to the stability of (Fe,Ni) metal. In our

model, most of carbonatite melt at the slab-

mantle interface would segregate into magma

diapir rather than disperse into surrounding man-

tle (Figure 2.15b). Moreover, since the carbonate

reservoir is replenished by continuous subduc-

tion, the limited amount of iron in the mantle

above the slab may be totally oxidized with time.

Most extensive redox interaction is expected at

the beginning of carbonate melting, when the

first diapir rises up through the pristine Fe

0

-

bearing mantle from about 550 to 250 km depth.

All metallic iron on the route of this diapir

would inevitably react with carbonatite melt:

2Fe

d

3

RT

ADC

0

Mw

,

η

Wet

_

mantle

=

(2.7)

C. Carbon solubility in

carbonate melt is about 0.3wt% at the man-

tle conditions (Palyanov

et al

., 2005). Therefore,

carbonatite melt soon becomes supersaturated

with carbon, which causes diamond precipita-

tion (Figure 2.16). Reduction of CO

2

should also

be accompanied by silicate precipitation from the

melt. This ''redox freezing'' gradually reduces size

of the carbonatite diapir and its ascent rate by

about 30% and 50%, respectively, for an initial

+

CO

2

→

2FeO

+

where

A

is the constant of about 10 for equiax-

ial polycrystals (Vickers & Greenfie, 1967;

Kruzhanov & Stockhert, 1998),

C

0

is the silicate

solubility in carbonatite melt (silicate mole

fraction is about 0.24 at temperature of adiabat),

M

is the molar volume of silicate (3.93 m

3

/mol

for wadsleyite (Katsura

et al

., 2009)). Following

the fluid film model, the effective grain boundary

width,

w

, is of the order of 1-10 nm and the

diffusion coefficient of solute in film is the

same as an order of magnitude lower than that

in the bulk melt (Dysthe

et al

., 2003). Such

an analysis yields a viscosity of 8

10

16

Pa s

providing the ascent rate of 0.5m/year for

r

×

=

1 km (Figure 2.15a). Diapirs with such ascent

rate could consume all carbonatite, which could

be potentially extracted from the subducting

slab (Figure 2.15b). Nominally, rising diapirs

could support an upward CO

2

flux, two orders of

magnitude higher than the subduction CO

2

flux.

Note that the maximum rate of diapir ascent

through the ''dry'' mantle cannot exceed the

infiltration rate. According to our preliminary

estimations this rate approaches to 0.5m/year

(Figure 2.15a). However, diapirs following behind

the first one would not have such a rate limitation

if carbonatite saturated conduits are established.

Rohrbach & Schmidt (2011) suggested that car-

bonatite melt is unstable, when at depths greater

Fig. 2.16

Carbon loss of the carbonatite melt during

diapiric ascent due to carbonate reduction by metallic

iron dispersed in the mantle. We assume

C

(Fe

0

)

0.1 wt % in the depth range of 660-250 km

(Frost

et al

., 2008).

=