Geoscience Reference

In-Depth Information

and velocity of molten iron-light-element alloy

systems. There are two ways to measure the

density of the materials forming the liquid core

under static high pressure conditions. One is the

X-ray absorption method, and the other is the

sink-float method using density markers.

The X-ray absorption method has been in-

troduced by Katayama

et al

. (1993) to measure

the density of various metallic liquids at high

pressure. This method is based on the Lambert-

Beer law:

Absorption Profile

In(I/I

0

)

I

0

I

ion chamber

ion chamber

Si (111)

SPring

−

8

BL22XU

slits

50

×

50

μ

m

DIA-type cubic

anvil apparatus

(SMAP-1)

I

=

I

0

e

−

μρ t

where

I

0

is the incident X-ray intensity,

I

is the

intensity of the passed X-ray,

μ

is theX-ray mass

absorption coefficient, and

t

is the sample thick-

ness. When we know the X-ray mass absorption

coefficients and the sample thickness, we can

determine the density of the sample precisely.

A monochromatic X-ray is used for the X-ray

source, and large volume presses are used for

the measurements. Katayama

et al

. (1993) used a

DIA-type cubic apparatus, whereas Sanloup

et al

.

(2000) used the Paris-Edinburgh cell (a Troid-type

cell designed for neutron diffraction) to measure

X-ray absorption. To measure the intensity ratio

of the incident and transmitted X-rays, Katayama

et al

. (1993) used two ion-chambers placed in the

front and in the back of the press, whereas San-

loup

et al

. (2000), Chen

et al

. (2005), and Terasaki

et al

. (2010) used the X-ray radiographic imaging

to determine of the absorption profile. Figure 8.12

shows an example of the experimental setup for

the X-ray absorption method using the DIA cu-

bic press with two ion chambers. In this setup,

the press with the sample cell assembly moves

horizontally perpendicular to the X-ray beam.

Another procedure for determination of the

density of the melt is the sink-float method,

which was used by Kushiro (1978), Agee and

Walker (1988), and Ohtani

et al

. (1993) for sili-

cate melts and by Balog

et al

. (2001) and Nishida

et al

. (2008) for metallic Fe-S melts. When we

know the equation of state of the density marker

precisely, we can bracket the bound of the density

of the melt by observation of sinking or floating

of the standard material at high pressure and

temperature. Composite density markers (inner

Fig. 8.12

The experimental setup for the X-ray

absorption method at the beamline BL22XU of

Spring-8. A monochromatized X-ray is introduced to

the DIA type cubic press. Two ion chambers are used

for the measurement of intensities of an incident X-ray

(

I

0

) and a passed X-ray (

I

). Reproduced with permission

of Elsevier.

Pt

Al

2

O

3

Al

2

O

3

1,34 mm

1 mm

Pt

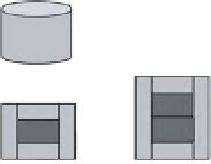

Fig. 8.13

An example of the density marker composed

of the outer alumina tube with alumina caps, and a Pt

rod in the center (Tateyama

et al

., 2011).

core:W or Pt, outer shell: corundum) were used

by Balog

et al

. (2001). Similarly, a cylindrical com-

posite density marker was used by Nishida

et al

.

(2008) to determine the density of the metallic

melt. They introduced in situ X-ray radiographic

imaging to observe floating and sinking of the

density marker. Figure 8.13 is an example of the

density marker composed of the outer alumina

tube with alumina caps, and a Pt rod in the center.

Figure 8.14 is an X-ray radiographic image, which

shows floating of the sample at high pressure and

temperature (Tateyama

et al

., 2011).

(b) Physical properties of Fe-S, Fe-Si, and Fe-C

melts at high pressure

Figure 8.15 shows the