Geoscience Reference

In-Depth Information

of light elements needs to be considered. We need

more precise experimental data on the melting

temperature of pure iron and iron-light-element

systems.

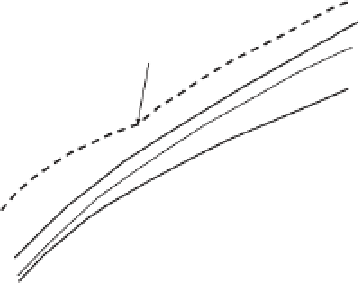

Figure 8.10 shows the temperature profile of

the core estimated by Terasaki

et al

. (2011) based

on the Fe-Si-O system. The upper and lower

bounds of the ICB temperature correspond to

the liquidus and solidus temperatures at ICB

pressure, respectively. The liquidus temperature

of Fe

75

O

5

S

20

at 136 GPa was determined to be

3600

Fe

75

O

5

S

20

alloy

4000

Fe

Liq

+

Liquidus

Solidus

Melting of pure Fe

3000

Liq

Fe

+

FeO

+

Liq

2000

Fe

+

FeO

+

Fe

3

S

200 K, which gives a lower bound of the

temperature at CMB (Figure 8.10). The solidus

and liquidus temperatures at 330 GPa, obtained

using extrapolation by the Simon equation, are

4380

±

1000

0

40

80

120

160

P, GPa

±

±

350 K, respectively, pro-

viding the lower and upper bounds of temperature

at the ICB for this composition. The ICB tem-

perature was estimated previously by using the

melting temperature of pure iron determined by

various procedures, and the present upper bound

of the ICB temperature of 5630

200 and 5630

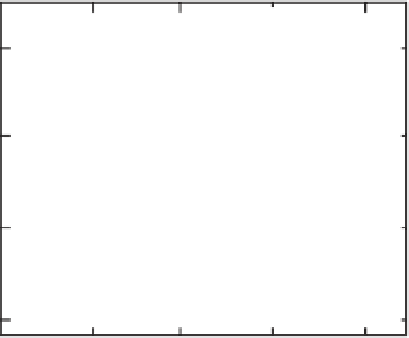

Fig. 8.9

The phase and melting relations of Fe

75

O

5

S

20

alloy in the Fe-O-S system determined by Terasaki

et al

. (2011). The liquidus phase is hcp-Fe, and the

second liqudus phase is FeO. Fe

3

Sisconsumedfirstat

the solidus temperature. The solidus temperature of

this system is very close to the eutectic temperature of

the Fe-Fe

3

S system, indicating that the effect of FeO in

the melting relation of the Fe-O-S system is very

small. Reproduced with permission of Elsevier.

±

350 K is lower

than the previous estimate; i.e.

∼

170 K lower

than that (T

mFe

=

5800 K) estimated by the di-

amond anvil cell experiment (Ma

et al

., 2004),

2007; Kamada, 2011), and the effect of FeO pres-

ence on the solidus temperature seems to be

negligible under megabar conditions.

6000

hcp-Fe (Ma

et al

., 2004)

T

L

ad

(c) Constraints on temperature of the core based

on melting experiments

The melting relations

can be used to estimate the thermal state of

the core. The temperatures at ICB and CMB

can be estimated by using the melting relations

of the iron-light-element systems. The melting

temperature of iron has been calculated to be

6700

5000

Liquidus

4000

T

s

ad

3000

Solidus

600 K at the ICB (e.g., Alfe

et al

., 1999),

which is close to the melting temperature de-

termined by the shock experiments (Brown &

McQueen, 1980, 1986; Yoo

et al

., 1993; Nguyen

& Holmes, 2004). The ICB has been assumed to be

the solid-liquid phase boundary and the melting

temperature of pure iron has been used to con-

strain the ICB temperature. However, the temper-

ature at the ICB, as estimated from the melting

temperature of pure iron, remains uncertain and

varies from 4000 to 7000K. In addition, the effect

±

CMB

ICB

350

100

150

200

250

300

Pressure, GPa

Fig. 8.10

The temperatures at the ICB and CMB

estimated based on the liquidus and solidus

temperatures of the Fe-Si-O system by Terasaki

et al

.

(2011). See the text in detail.

T

L

ad

and

T

S

ad

are the

adiabatic temperature profiles decompressed from the

liquidus and solidus temperatures at ICB, respectively.

Reproduced with permission of Elsevier.