Geoscience Reference

In-Depth Information

Examples were shown for B1 (NaCl structure)

(Ashby & Brown, 1982) and garnet (Karato

et al

.,

1995a) (see Figure 4.15a,b). (Karato, 1989c) ex-

tended such a study to oxides and silicates and

noted that there is a large variation in plastic prop-

erties among oxides and silicates even after the

normalization ((Ashby and Brown, 1982) treated

oxides as a single group). In particular, this study

showed that a transition to a dense structure does

not necessarily lead to a high resistance to plas-

tic deformation. (Karato, 2011a) extended such

an analysis to include the influence of transition

to the metallic state and the influence of the

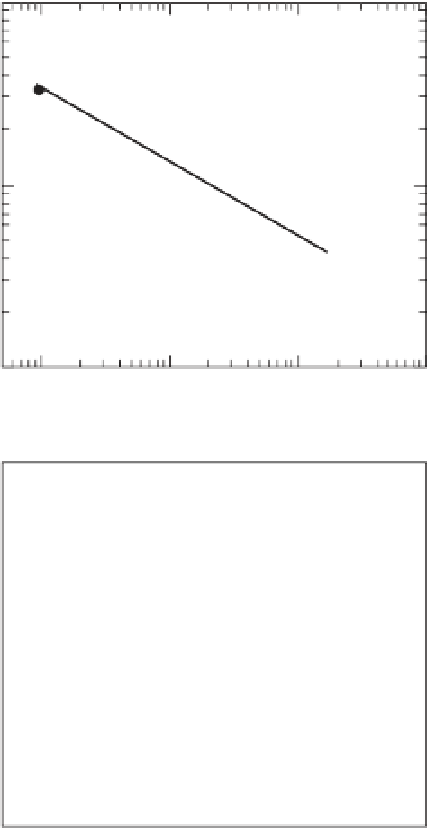

B1

olivine

10

3

T

=

1473 K

•

10

−

4

s

−

1

=

10

2

r

=

1.20

+

/

−

0.05

B2 transition (Figure 4.15c).

Such an analysis shows that unlike elastic-

ity where a phase transformation to a denser

structure leads to a higher elastic constant

with a minor correction for the influence of

coordination (the Birch's law - Liebermann,

1982), density does not play an important role

in high-temperature plasticity. The Birch's law

of correspondent state does not work for plastic

properties. In many cases, a change in crystal

structure has only a modest effect. An increase in

melting temperature, therefore, will increase the

effective viscosity modestly. Also, if a transition

to metallic state occurs in the deep mantle

of super-Earths (

→

10

10

−

1

10

2

1

10

fH

2

O, GPa

(a)

9000

8000

7000

6000

T

=

1473 K

•

=

10

−

4

s

−

1

5000

4000

1TPa), then a substantial

reduction in effective viscosity will occur.

∼

V*

w

=

24

+

/

−

2 cm

3

/mol

3000

2000

0

0.5

1

1.5

2

2.5

4.4.5 Influence of partial melting

Pressure, GPa

(b)

Figure 4.16 summarizes the experimental obser-

vations on the influence of partial melting

on plastic deformation of olivine aggregates

(Kohlstedt, 2002). Deformation experiments

were performed both for the diffusion creep

and dislocation creep regimes. The influence of

partial melting is stronger in the diffusion creep

regime than in the dislocation creep regime.

This is due to the fact that in the diffusion

creep regime, fast diffusion in the melt as well

as stress concentration enhances deformation

whereas in the dislocation creep regime only

stress concentration enhances deformation.

They proposed an empirical formula to explain

Fig. 4.14

Analysis of the influence of water on creep

strength in olivine under water-saturated conditions

(after Karato & Jung, 2003). (a) the determination of the

water content exponent

r

. (b) the determination of the

activation volume

V

wet

(shown as

V

w

). Reproduced

with permission of Taylor & Francis.

temperature,

T

m

, and stress by shear modulus,

μ

,

then most of the data fall into a master curve,

F

T

ε

(

T

,

P

,

σ

)

ν

D

σ

μ

(

P

)

=

T

m

(P)

,

(4.18)