Geoscience Reference

In-Depth Information

deformation is modified by the presence of a

liquid phase. Various processes may affect the

plastic properties of such a solid-liquid mixture

including (i) chemical reaction between solid

and liquid (dissolution-precipitation), (ii) fast

diffusional mass transport through liquid phase,

and (iii) stress concentration.

The influence of chemical reaction (dissolution-

precipitation) has been studied extensively in

relation to so-called ''pressure-solution'' creep

(e.g., Rutter, 1976; Shimizu, 1994; Spiers

et al

.,

2004). This mechanism is essentially the same

as grain-boundary diffusion creep (Coble creep),

but because diffusion is fast in the liquid, the

rate of deformation is often controlled by the

rate of chemical reaction at the grain-liquid

interface (Spiers

et al

., 2004). The influence of

processes (ii) and (iii) were analyzed by Cooper

and Kohlstedt (1986); Kohlstedt (2002). They

showed that the presence of partial melt has

only modest influence on creep rate (see a later

part of this chapter). In contrast, Takei and

Holtzman (2009a,b,c) presented a more sophisti-

cated analysis of stress states at grain-boundaries

and concluded that the influence of partial

melting is stronger, a factor of

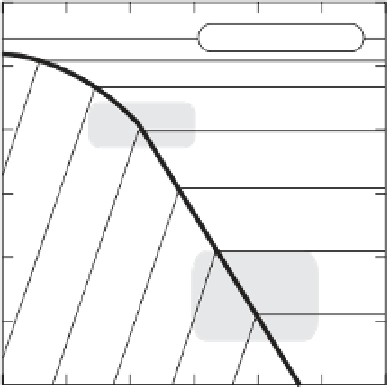

4.2.6 Deformation mechanism map

Because of the presence of multiple mechanisms

of plastic deformation, it is convenient to use

some diagrams to illustrate the parameter space

where one mechanism dominates over others.

Such a diagram is called a deformation mecha-

nism map (Frost & Ashby, 1982). In many cases,

the competing mechanisms are independent, so

these diagrams simply show the mechanisms

with the largest strain-rate under various condi-

tions. Because strain-rate depends on a number of

parameters (temperature (

T

), pressure (

P

), grain-

size (

L

), stress (

σ

), water content (

C

W

)), such a

diagram must in general be presented in a multi-

dimensional space. However, a two-dimensional

diagram is easy to use for practical purposes,

and therefore in most cases, such a diagram is

usually constructed on a two-dimensional space

keeping other parameters fixed. An example of de-

formation mechanismmap is shown in Figure 4.4

10

4

10

3

Peierls mechanism

1

10

3

10

−

3

5 reduction in

viscosity even at a small melt fraction, 10

−

3

%

(see Chapter 3, this volume). The reason for this

discrepancy is not well understood. Modeling

diffusion creep is complicated because the stress

state and diffusional flux have strong interaction

and these two must be solved self-consistently as

shown by Raj and Ashby (1971). For dislocation

creep, there is no mechanism to enhance creep

significantly at a small melt fraction. The same

is true for diffusion creep controlled by volume

diffusion. In some Earth sciences literatures,

boundary diffusion controlled diffusion creep is

exclusively considered (e.g., Mei & Kohlstedt,

2000a; Hirth & Kohlstedt, 1995a; Kohlstedt,

2002). However, interplay between volume and

boundary diffusion is complicated in ionic solids

and both boundary diffusion-controlled and

volume diffusion-controlled creep behaviors are

found in many oxides depending on the grain-size

and temperature (e.g., Cannon & Coble, 1975;

Gordon, 1973; Li

et al

., 1996).

∼

lab

10

2

10

−

6

•

=

10

−

9

s

−

1

10

1

Power-law creep

diffusion creep

10

−

12

10

0

Earth

10

−

15

10

−

1

10

−

2

10

−

4

10

−

3

10

−

2

10

−

1

10

2

1

10

Grain-size, mm

Fig. 4.4

A deformation mechanism map for olivine

(after Karato, 2010b) P

=

7GPaandT

=

1700 K

(

300 km depth), dry condition. Dominant defor-

mation mechanisms in the hot mantle are either

diffusion or power-law (dislocation) creep although in

the laboratory conditions many mechanisms may

compete depending on the precise conditions. A similar

conclusion is obtained for other minerals (see Karato,

1998b). Reproduced with permission of Elsevier.

∼