Geoscience Reference

In-Depth Information

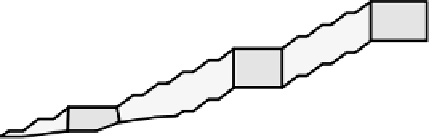

Wherever possible, the advancing faces of each lift should attempt to develop a

convex configuration to encourage three-dimensional restraint effects. In addition,

the advancing slope should constitute a buttress to provide the appropriate

containment and stability of waste rock. These buttresses must also be constructed

of high geotechnical quality waste rock, with low fines waste. Fines waste with high

water content or low-resistance must be encapsulated in cells located behind the

buttress. In order to manage the waste materials properly, sand and fines content of

the waste should be checked periodically [MOR 06].

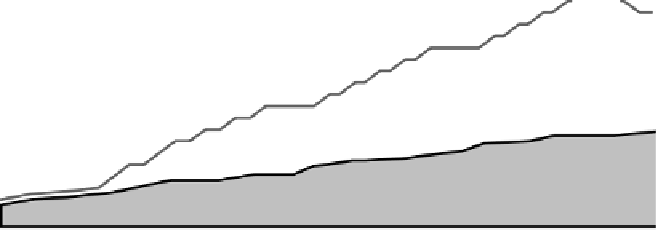

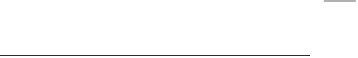

Tau/Sigma Ratio: 0.33

1.483

4.0

3.9

3.8

S3

3.7

S1

3.6

S4

S3

3.5

S2

3.4

S1

S5

S4

3.3

S3

3.2

S2

S1

3.1

S4

3.0

2.9

2.8

2.7

0.0

0.2

0.4

0.6

0.8

1.0

1.2 1.4

1.6

1.8

2.0

2.2

2.4

2.6 2.8

3.0

3.2

3

Horizontal Distance (m) (x 1000)

Distancia Horizontal (m) (x 1000)

Figure 4.18.

Example of the stability analysis of a high waste rock dump by

limit equilibrium methods - static cases

[ARC 06-07]

4.7. Operation considerations

Designing a HWRD must take into account the many operational aspects that

require specific solutions.

4.7.1.

Basal drainage system

A drainage system is a critical part in the conception of a waste rock dump.

General practice, used in most mines, is to exploit the segregation into grain sizes

during dumping and to rely on the permeability of the coarser layers deposited at the

bottom of the dump lifts, formed mostly by large sized particle and blocks. This

practice has proven to be valid for many cases where “normal” conditions prevail.

There are also many situations where a drainage system of this type could fail,

however, in the sense that it will not allow free drainage of the dump. This could

Search WWH ::

Custom Search