Geoscience Reference

In-Depth Information

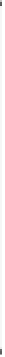

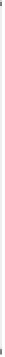

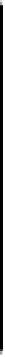

To evaluate this phenomenon, the grain size of the waste rock was systematically

analyzed after each test. The grain size distribution curves of ROM and leached

waste rock, before and after oedometric tests, are shown in Figure 4.5 for the

different vertical stresses applied and summarized in terms of evolution of d

10

and

d

60

. These diameters correspond to the openings of the sieves through which 10%

and 60% in weight of material pass, respectively, in Table 4.3.

For the two grain size distributions of the analyzed waste rock, the results show

that the leached waste rock, with an initial grain size distribution finer than that of

the ROM, presents a stronger grain size evolution. This is probably related to the

effect of forced leaching on the individual strength of the particles.

Percent Passing

# 200

# 4

8"

100

90

ROM WR before testing (< 8")

ROM WR after testing at σ'

v

= 4 MPa

ROM WR after testing at σ'

v

= 8 MPa

ROM WR after testing at σ'

v

= 12 MPa

Leached WR before testing (homothetic)

Leached WR after testing at σ'

v

= 4 MPa

Leached WR after testing at σ'

v

= 8 MPa

Leached WR after testing at σ'

v

= 12 MPa

80

70

60

50

40

30

20

10

0

0.1

1

10

100

Particle Diameter (mm)

Figure 4.5.

Grain size distributions of ROM and leached waste rock (WR) before and after

oedometric tests. Tests performed on large-scale samples

4.4.3.4.

Saturated permeability

Once the samples became saturated under the applied vertical stress, infiltration

tests at a constant hydraulic head were carried out to determine the permeability

coefficient in saturated condition for both ROM and leached waste rock. Low

hydraulic gradients were imposed to induce a laminar infiltration flow in these

materials. The permeability coefficients obtained are presented in Table 4.4.

Search WWH ::

Custom Search