Geoscience Reference

In-Depth Information

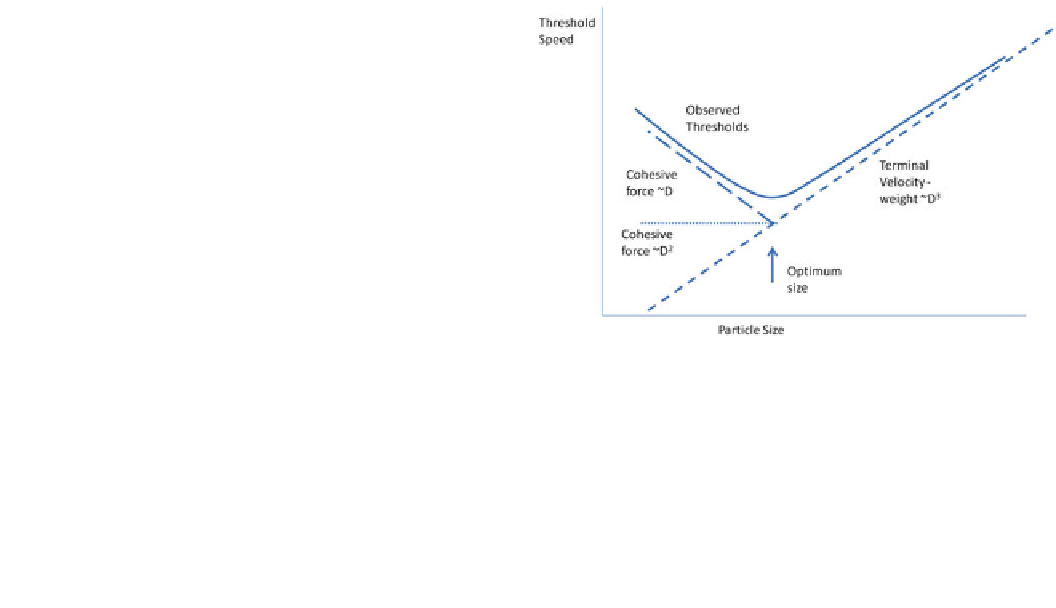

Fig. 4.8

A schematic of the threshold speed and how it depends on

diameter (shown on unlabelled, but logarithmic, axes). Weight varies

as the cube of diameter, whereas lift and drag vary roughly as the

square, thus the threshold windspeed that balances them is propor-

tional to size. At very small sizes, a cohesive force proportional to

diameter (i.e., a cohesive stress inversely proportional to diameter) will

dominate and the threshold will be inversely proportional. Where the

cohesion and weight are about the same, the overall resistance to

motion is a minimum, and thus the threshold speed is the lowest: the

saltation 'optimum'. For different gravity, different cohesion param-

eters, different fluid density, etc., the numbers will all be different, but

the overall shape of the curve will be the same

Fig. 4.7

Measurements of the friction velocity (i.e., the slope of

speed vs. logarithm of height) are linearly correlated with winds at

9.5 m height. These measurements are from Death Valley (from

Greeley et al. (1991b)), and show u**0.05U

9.5

. Image NASA

(like a wing) can be written as Eq.

4.1

, i.e., D/S =

0.5C

d

q

f

U

2

with all the parameters as before, except here the

drag coefficient is not that of a spherical or similar body, but

is the friction coefficient of a surface. That (as before)

depends on roughness and Reynolds number, but broadly

speaking is around 0.001 for 'smooth' surfaces and maybe

0.01 for rough ones. Now, we can rearrange Eq.

4.1

to

calculate the wind stress on the ground as s = D/S, and

rearrange Eq.

4.3

to say s =u

2

/q

f

, and we find then simply

that u*/U*(0.5C

d

)

0.5

(some definitions of C

d

may result in

the 0.5 not appearing, but the square root means this doesn't

matter terribly). In other words, u

*

/U*20, give or take a

little. While this rule of thumb lacks rigor, it is a handy way

to grapple with the numbers at least approximately. And,

indeed,

A variety of mechanisms can play a role, with different

behavior. If we imagine the cohesion is due to some sort of

weak strength like a glue between grains, then it would have

a constant force per unit area. In that case, the threshold

speed as a function of size would be flat—constant—cor-

responding to the speed at which the aerodynamic stress

equals the failure stress of the glue. On the other hand, and

damp sand may behave a bit like this, imagine the cohesion

force is a linear function of diameter. Surface tension of

liquids can behave this way. In this case, the cohesion force

grows linearly with diameter, whereas the aerodynamic

stress (ignoring the Reynolds number effect) grows with the

square of diameter. Thus the windspeed at which these two

will balance, and thus the threshold windspeed for motion,

will vary as the reciprocal of size. This is shown schemat-

ically in Fig.

4.8

.

Bagnold conducted extensive wind tunnel measure-

ments, both in the field and in the laboratory, to understand

the flow conditions that led to motion. Greeley, Iversen and

White in the 1970s conducted many further experiments,

using particles made of different materials and using air of

different density. These latter experiments tend to report

their results with the drag coefficient formulation, and the

cohesion

field

measurements

show

just

this

sort

of

relationship.

For large particles, it is the weight that dominates, and so

the threshold stress (i.e., friction velocity, or the corre-

sponding windspeed) relates closely to the terminal veloc-

ities shown in

Sect. 4.1

. Bigger particles have larger

weights and thus higher threshold speeds, and in principle

arbitrarily

small

particles

would

have

arbitrarily

small

threshold speeds.

However, at small sizes, adhesion (or cohesion) forces

take over. This tendency is evident in the kitchen: icing

sugar and granular sugar are the same stuff, just with dif-

ferent particle size. Dig some out with a spoon, and granular

sugar (with a grain size usually 0.5 mm or more) will

slump, making a conical pit with an angle of about 30, set

by the friction between particles. But dig a hole in icing

sugar, and it can have vertical walls—the cohesion between

the smaller grains is enough to prevent the walls failing.

This cohesion is also what means small particles with slow

terminal velocities do not easily get lifted of a surface.

formulation,

buried

together

in

a

'threshold

parameter' A.

They use a rather ugly empirical formulation for this—it

fits the data, although it is not clear how applicable it may

be to ices or organics on Titan. Since both the drag and

Search WWH ::

Custom Search