Geoscience Reference

In-Depth Information

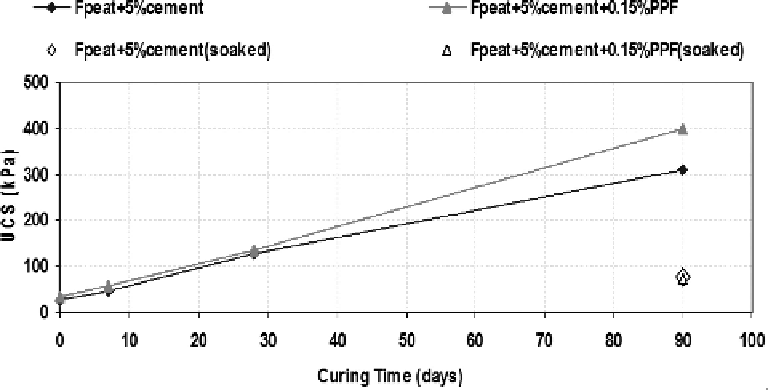

Figure 7.22

Unconfined compressive strength (UCS) values for fibrous peat and 5% OPC with and

without polypropylene fibres (PPF) vs. curing time.

The minimum dosage rate of PPF recommended for concrete mixes starts at

0.6 kgm

−

3

(Sika Fibres 2005). Also, Tang

et al.

(2007) tried 0.05, 0.15 and 0.25% (by

soil weight) of polypropylene fibres (PPF) through UCS tests to find the optimum PPF

amount to strengthen cement-treated clay soil.

Kalantari

et al.

(2011) examined polypropylene fibre (PPF) as an additive used

in OPC-treated fibrous peat samples, and its effect was evaluated through UCS. Air

curing was used to cure the OPC treated fibrous peat samples with PPF.

Different types of UCS test samples made of fibrous peat with a moisture content

of 198% and various amounts of OPC (5, 15, 20, 30 and 50%) and 0.15% PPF

were prepared, and then cured for up to 90 days. UCS tests were then conducted on

stabilized samples immediately after mixing (0 day), 7, 28 and 90 days. Soaked UCS

tests were also conducted on 90 days air cured samples by submerging them in water

for seven days prior to being tested. The results are shown in Figures 7.22-7.26.

UCS tests were also conducted on plain (untreated) fibrous peat samples imme-

diately after mixing (0 day) and after 90 days, in unsoaked (cured in air), and

soaked (cured 90 days in air, and then soaked for seven days). The result is shown

in Figure 7.27.

The results in Figures 7.22-7.27 show that:

(a)

As the OPC amount is increased in stabilized samples with or without PPF, the

immediate (0 day) and soaked UCS values increase as well.

(b)

Addition of 0.15% polypropylene to the OPC-treated fibrous peat samples

increases the UCS values of the air cured stabilized samples.

(c)

UCS values increase from 28 days to 90 days of curing periods for samples

containing 5% OPC by over 142% (from 128 to 310), and 196% (from 135 to

400), and for 15% by over 135% and 196%, and also for samples containing