Geoscience Reference

In-Depth Information

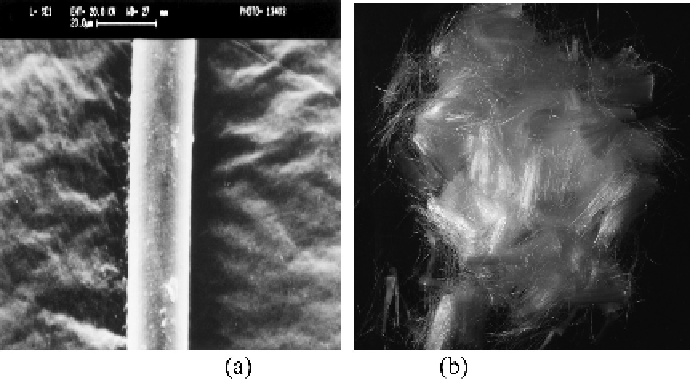

Figure 7.20

Polypropylene fibres: (a) SEM image (

after Kaniraj

and Gayathri, 2003); (b) photograph

showing the discrete short PP fibre (

after

Tang

et al.

, 2007).

(d)

Dosage rates of 5, 15 and 25% of OPC along with 5 and 10% of silica fume

increase the soaked UCS values of undisturbed fibrous peat by a factor as high

as 10.

7.8.4 Polypropylene fibres (PPF)

Polypropylene (PP) is a versatile thermoplastic material which is produced by polymer-

izing monomer units of polypropylene molecules into very long polymer molecules or

chains in the presence of a catalyst under carefully controlled heat and pressure. It has

a good combination of properties, is cheaper than many other materials that belong

to the family of polyolefins and it can be manufactured using various techniques. In

general, polypropylene (Figure 7.20) is resistant to alcohols, organic acids, esters and

ketones. Its general use in the construction industry is to reinforce concrete to control

cracks as well as for increasing their load-bearing capacity and durability (Mullik

et al.

,

2006). Some properties of polypropylene fibres are listed in Table 2.14. Polypropylene

fibres have also been used successfully as a non-chemical admixture to strengthen var-

ious types of soil, such as sands and clays, in conjunction with a binding agent such as

Portland cement and or lime (Kaniraj and Gayathri, 2003; Tang

et al.

, 2007).

Studies have also been carried out by several researchers (Gray and Ohashi, 1983;

Consoli

et al.

, 1998, 2002, 2009; Yetimoglu and Salbas 2003; Yetimoglu

et al

., 2005;

Ranjan

et al

., 1996; Park and Tan, 2005; Tang

et al

., 2007; Chauhan

et al

., 2008)

on the influence of fibre inclusion on the mechanical behaviour of cemented soil. In

general, reports in the literature show that the randomly distributed fibres can be

used to overcome the drawbacks of using cement alone, such as the high stiffness

and brittle behaviour of the stabilized soil. In a series of laboratory unconfined com-

pressive strength tests, the raw specimens attained a distinct axial failure stress at an