Geoscience Reference

In-Depth Information

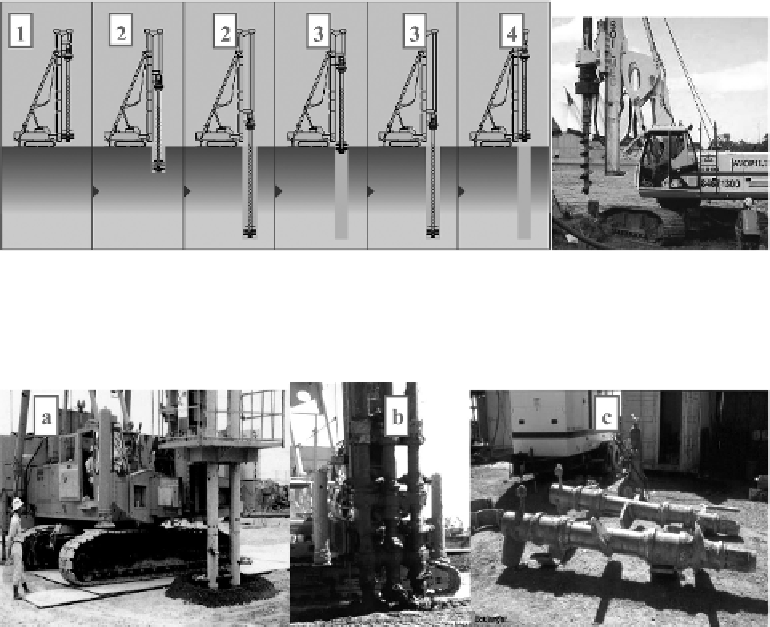

Figure 6.16

The steps in the ras-columns system (

after

Raito Kogyo, 2006) and its mixer (SDFEC, 2007;

Kazemian and Huat, 2009b).

Figure 6.17

(a) CDM machine with two augers (

after

Raito Kogyo, 2006), (b) CDM machine with

three augers (

after

Keller, 2005), (c) two augers which have been parted-off (

after

Balvac,

2008).

(Figure 6.16 (1)). This is followed by penetration, whereby after passing through a dry

excavation zone slurry should be injected without any jetting (Figure 6.16 (2)). The

third step is churning or moving the head up and down to mix the soil and cement

thoroughly (Figure 6.16 (3)). Finally, in the completion step the head is withdrawn

and the soil-cement column is completed (Figure 6.16 (4)).

6.4.2 Cement deep mixing system (CDM)

The second method is related to DSM and is one of the DMM methods, known as

cement deep mixing (CDM). As mentioned earlier, in this method, a series of overlap-

ping augers and mechanical mixing shafts are used. Figures 6.17(a) and 6.17(b) show

CDM machines with two and three augers respectively. Two augers which have been

parted-off (detached) are shown in Fig. 6.17(c).

CDM is normally used in soft soil that contains mineral soils such as clay or sand. In

some conditions where mineral soils are absent, sand should be added before mixing in