Geoscience Reference

In-Depth Information

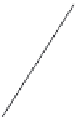

Rotating arm

Influent spray

Rock Bed

Influent

Underdrain

System

Euent

FIGURE 24.4

Schematic of cross-section of a trickling filter.

24.5.1 t

riCKling

F

filter.

p

roCess

C

alCulations

Several calculations are useful in the operation of trickling filters; these include hydraulic loading,

organic loading, and BOD and SS removal. Each type of trickling filter is designed to operate with

specific loading levels. These levels vary greatly depending on the filter classification. To operate

the filter properly, filter loading must be within the specified levels. The main three loading param-

eters for the trickling filter are hydraulic loading, organic loading, and recirculation ratio.

24.5.1.1 Hydraulic Loading Rate

Calculating the hydraulic loading rate is important in accounting for both the primary effluent as

well as the recirculated trickling filter effluent. These are combined before being applied to the filter

surface. The hydraulic loading rate is calculated based on filter surface area. The normal hydraulic

loading rate ranges for standard rate and high rate trickling filters are

Standard rate—25 to 100 gpd/ft

2

or 1 to 40 MGD/ac

High rate—100 to 1000 gpd/ft

2

or 4 to 40 MGD/ac

Key Point:

If the hydraulic loading rate for a particular trickling filter is too low, septic conditions

will begin to develop.

■

EXAMPLE 24.22

Problem:

A trickling filter 80 ft in diameter is operated with a primary effluent of 0.588 MGD and

a recirculated effluent flow rate of 0.660 MGD. Calculate the hydraulic loading rate on the filter in

units gpd/ft

2

.

Solution:

The primary effluent and recirculated trickling filter effluent are applied together across

the surface of the filter; therefore, 0.588 MGD + 0.660 MGD = 1.248 MGD = 1,248,000 gpd:

2

2

2

Circular surface area

=

0.785

×

(diameter)

=

0.7

85

×

(80ft)

=

5024 ft

1,248,000 gpd

5024 ft

2

Hydraulic loadingrate

=

=

248.4 gpd/ft

2

Search WWH ::

Custom Search