Geoscience Reference

In-Depth Information

TABLE 16.2

Empirical Parameters for Equation 16.13

Tray

Metric

Ψ

Engineering

Ψ

Bubble cap

0.0162

0.1386

Sieve

0.0140

0.1196

Valve

0.0125

0.1069

Note:

Metric Ψ is expressed in m

0.25

hr

0.5

kg

0.25

for use

with

Q

expressed in m

3

/hr and ρ

g

expressed in

kg/m

3

. Engineering Ψ is expressed in ft

0.25

min

0.5

lb

0.25

for use with

Q

expressed in cfm and

ρ

g

expressed in lb/ft

3

.

Source:

Adapted from USEPA,

Wet Scrubber System

Study

, NTIS Report PB-213016, U.S.

Environmental Protection Agency, Research

Triangle Park, NC, 1972.

■

EXAMPLE 16.5. PLATE TOWER DIAMETER

Problem

: For the conditions described in Example 16.2, determine the minimum acceptable diam-

eter if the scrubber is a bubble cap tray tower absorber. The trays are spaced 0.53 m (21 in.) apart

(USEPA, 1981, p. 4-34).

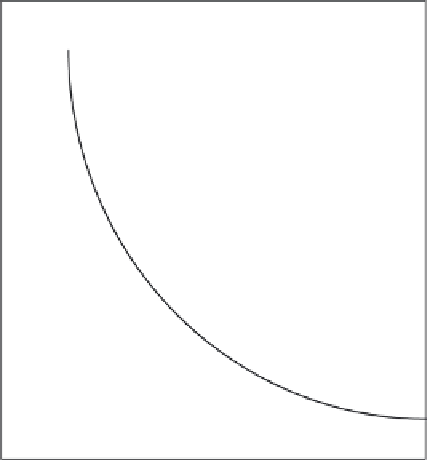

Tray Spacing, Inches

15

18

21

24

27

30

1.5

1.4

1.3

1.2

1.1

1.05

1.0

0.9

0.4

0.53

0.6

0.8

Tray Spacing, Meters

FIGURE 16.10

Tray spacing correction factor. (Adapted from USEPA,

APTI Course 415: Control of

Gaseous Emissions

, EPA 450/2-81-005, U.S. Environmental Protection Agency Air Pollution Training

Institute, Washington, DC, 1981, p. 4-33.)

Search WWH ::

Custom Search