Geoscience Reference

In-Depth Information

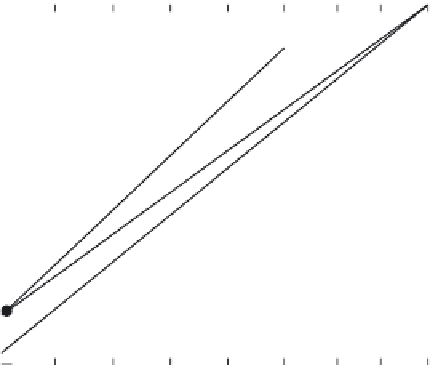

0.03

C

B

38.4

Operating

line

0.02

57.6

0.01

Minimum operating line

A

0

0.0002

0.0004

0.0006

0.0008

FIGURE 16.7

Solution to Example 16.2. (From USEPA,

APTI Course 415: Control of Gaseous Emissions

,

EPA 450/2-81-005, U.S. Environmental Protection Agency Air Pollution Training Institute, Washington, DC,

1981, p. 4-21.)

Figure 16.7 illustrates the graphical solution to this problem. The slope of the minimum operating

line multiplied by 1.5 is the slope of the actual operating line (line

AC

):

38.4 × 1.5 = 57.6

16.3.4 p

aCKed

t

oWers

and

p

late

t

oWers

16.3.4.1 Sizing the Packed Tower Absorber Diameter

The main parameter that affects the size of a packed tower is the gas velocity at which liquid drop-

lets become entrained in the existing gas stream. Consider a packed tower operating at set gas and

liquid flow rates. By decreasing the diameter of the column, the gas flow rate (m/s or ft/s) through the

column will increase. If the gas flow rate through the tower is gradually increased by using smaller

and smaller diameter towers a point will be reached where the liquid flowing down over the pack-

ing begins to be held in the void spaces between the packing. This gas-to-liquid flow ratio is termed

the

loading point

. The pressure drop over the column begins to increase, and the degree of mixing

between the phases decreases. A further increase in gas velocity causes the liquid to completely fill

the void spaces in the packing. The liquid forms a layer over the top of the packing, and no more liq-

uid can flow down through the tower. The pressure drop increases substantially, and mixing between

the phases is minimal. This condition is referred to as

flooding

and the gas velocity at which it occurs

is the

flooding velocity

. Using an extremely large diameter tower would eliminate this problem.

However, as the diameter increases, the cost of the tower increases (USEPA, 1981, p. 4-22).

Normal practice is to size a packed column diameter to operate at a certain percent of the flood-

ing velocity. A typical operating range for the gas velocity through the towers is 50 to 75% of the

flooding velocity. It is assumed that by operating in this range, the gas velocity will also be below

the loading point. A common and relatively simple procedure to estimate the flooding velocity (thus

minimum column diameter) is to use a generalized flooding and pressure drop correlation. One

version of the flooding and pressure drop relationship in a packed tower is shown in Figure 16.8.

This correlation is based on the physical properties of the gas and liquid streams and tower packing

characteristics. The procedure to determine the tower diameter is summarized in the following set

of calculations:

Search WWH ::

Custom Search