Geoscience Reference

In-Depth Information

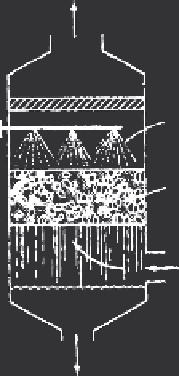

Clean gas out

Liquid in

Packing material

Dirty gas in

Liquid and pollutant out

FIGURE 16.2

Typical countercurrent-flow packed tower (From USEPA,

Control Techniques of Gases and

Particulates

, U.S. Environmental Protection Agency, Washington, DC, 1971.)

of the liquid, (2) transfer across the gas-liquid interface, and (3) diffusion of the dissolved gas away

from the interface into the liquid (Davis and Cornwell, 1991). Several types of scrubbing towers

are available, including spray chambers (towers or columns), plate or tray towers, packed towers,

and Venturi scrubbers. Pollutant gases commonly controlled by absorption include sulfur dioxide,

hydrogen sulfide, hydrogen chloride, ammonia, and oxides of nitrogen.

The two most common absorbent units in use today are

plate towers

and

packed towers

. Plate

towers contain perforated horizontal plates or trays designed to provide large liquid-gas interfacial

areas. The polluted airstream is usually introduced at one side of the bottom of the tower or column

and rises up through the perforations in each plate; the rising gas prevents the liquid from drain-

ing through the openings rather than through a downpipe. During continuous operation, contact is

maintained between air and liquid, allowing gaseous contaminants to be removed, with clean air

emerging from the top of the tower.

The packed tower scrubbing system (Figure 16.2) is predominately used to control gaseous pol-

lutants in industrial applications, where it typically demonstrates a removal efficiency of 90% to

95%. Usually configured in a vertical fashion, the packed tower is literally “packed” with devices

(see Figure 16.3) with a large surface-to-volume ratio and a large void ratio offering minimum

resistance to gas flow. In addition, packing should provide even distribution of both fluid phases, be

sturdy enough to support itself in the tower, and be low cost, available, and easily handled (Hesketh,

1991). The flow through a packed tower is typically countercurrent, with gas entering at the bottom

of the tower and liquid entering at the top. Liquid flows over the surface of the packing in a thin film,

affording continuous contact with the gases. Though highly efficient for removal of gaseous con-

taminants, packed towers may create liquid disposal problems, become easily clogged when gases

with high particulate loads are introduced, and have relatively high maintenance costs.

16.3.1 s

olubility

Solubility is a function of both the temperature and to a lesser extent the pressure of the system. As

temperature increases, the amount of gas that can be absorbed by a liquid decreases (gases are more

soluble in cold liquids than in hot liquids). Gas phase pressure can also influence solubility. Pressure

affects the solubility of a gas in the opposite manner. By increasing the pressure of a system the

amount of gas absorbed generally increases. However, this is not a major variable in absorbers used

for air pollution control because they operate at close to atmospheric pressure (USEPA, 1981).

Search WWH ::

Custom Search