Geoscience Reference

In-Depth Information

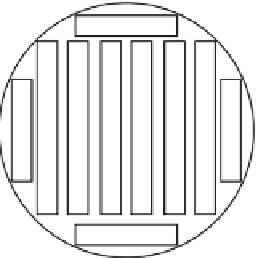

FIGURE 13.3

Diagram showing the number of 1-inch boards that can be cut from a specific log.

(width of the saw cut) of 1/4 inch. It is a rule based on a formula applied to each 4-foot section of the

log. For practical purposes, the scaling cylinder becomes a part of a cone (a frustum) with a taper of

2 in. over 16 feet. This rule generally results in a log scale relatively close to lumber tally when logs

are sawed in a reasonably efficient mill.

13.4.2.3 Smalian Cubic Volume Rule

The Smalian Cubic Volume rule requires measurement of the two inside bark diameters and the

length. It can be shown generally in the form:

Aa

L

+

V

=

×

(13.8)

2

where

V

= Volume in cubic feet (ft

3

).

A

= Large-end cross-section area (ft

2

).

a

= Small-end cross-section area (ft

2

).

L

= Log length (ft).

13.4.2.4 Log Rule Development

A log rule is a table or formula showing the estimated net yield for logs of a given diameter and

length. Ordinarily, the yield is expressed in terms of board feet of finished lumber, although a few

rules give the cubic volume of the log or some fraction of it. As noted earlier, the board foot is

equivalent to a plank 1 inch thick by 12 inches (1 foot) square; it contains 144 cubic inches of wood.

Although the board foot has been a useful and fairly definitive standard for the measure of sawed

lumber, it is an ambiguous and inconsistent unit for log scaling. Built into each log rule are allow-

ances for losses due to such things as slabs, saw kerf, edgings, and shrinkage. The volume com-

monly used for determining the board-foot content of saw lumber is

Thickness (in.)

×

Width(in.)

×

Leng

th (ft)

Boardfeet

=

(13.9)

12

At first glance and with the use of a simple equation (Equation 13.9), it would seem to be a rela-

tively simple matter to devise such a rule and having done so that should be the end of the problem.

But, it would seem so only to those who are unfamiliar with the great variations in the dimensions

of lumber that may be produced from a log, with variations in the equipment used in producing this

lumber and the skills of various operators, and, finally, with variations in the logs. All of these have

an effect on the portion of the total log volume that ends up as usable lumber and the portion that

becomes milling residue.

Search WWH ::

Custom Search