Geoscience Reference

In-Depth Information

which is to a major part compensated by grout injection. All these aspects cause

deformations in the direct environment, and they have to be taken into account in a

project design. During construction, specific monitoring is required to take timely

measures to prevent serious damage.

?

?

?

0

0

0

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

Zone

I

- sand and soft hard clay

- average workmanship

Zone

I

- sand and soft hard clay

- average workmanship

I

I

I

II

II

II

Zone

II

- very soft to soft clay

- limited depth

- significant depth below

bottom excavation

- construction difficulties

Zone

II

- very soft to soft clay

- limited depth

- significant depth below

bottom excavation

- construction difficulties

1

1

1

1

III

III

III

distance from excavation

maximum depth of excavation

distance from excavation

maximum depth of excavation

distance from excavation

maximum depth of excavation

distance from excavation

maximum depth of excavation

? =

? =

? =

? =

2

2

2

2

s

s

s

Zone

III

- very soft to soft clay to

significant depth

Zone

III

- very soft to soft clay to

significant depth

settlement

maximum depth of excavation

settlement

maximum depth of excavation

settlement

maximum depth of excavation

settlement

maximum depth of excavation

s =

s =

s =

s =

3

3

3

3

soft to medium clay stiff clay and cohesive sand cohesionless sand

soft to medium clay stiff clay and cohesive sand cohesionless sand

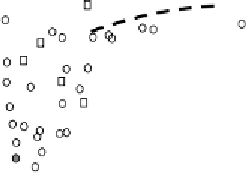

Figure 15.3 Environmental effect: settlements near excavations (Peck)

Since this environmental effect is rather case specific, only some general views

are available from experience. Peck (1969) has collected information of many

projects in the past and for the settlement adjacent to open cuts as a function of the

distance from the excavation, he suggested distinguishing three cases related to the

type of soil, shown in Fig 15.3. The data refer to excavations with a depth varying

between 6 and 23 metre where standard piles or sheet piles with cross bracing and

tiebacks have been used. Rankin (1988) published a comprehensive overview of

various empirical approaches for the assessment of surface movements due to soft-

ground tunnelling. In general, he adopts a Gaussian-curved bowl shape

characterised by a maximum depth, a length and a width. The position of the centre

of the bowl is 2

z

0

behind the tunnel face, and the border of the bowl is 2

z

0

ahead of

the tunnel face, where

z

0

is the depth of the tunnel. For cohesive soils, the

maximum settlement

w

max

is assumed to be related to the volume loss into the

tunnel. It does not hold for granular soils or stiff clays (see Fig 15.4). An

approximate trend can be obtained from case history data:

w

max

= (0.1

R

2

/

z

0

)

1.18

,

where

R

is the tunnel radius and

z

0

the depth of the tunnel axis. However the

experience so far with tunnelling induced surface settlements reveals a large

scatter. A recent state of the art review is presented by Mair (2011)

B

SOFT

-

GROUND TUNNELLING TECHNIQUES

There are various tunnelling techniques. In rigid soils, one may apply an open

boring front and even use explosives, but in soft permeable soils a shield is

required to keep soil and water under control and retain the front by a (pressure)

Search WWH ::

Custom Search