Geoscience Reference

In-Depth Information

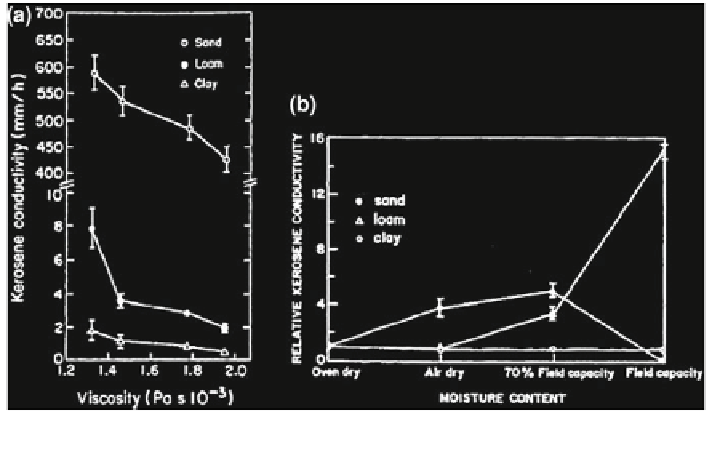

Fig. 12.47

Kerosene conductivity as affected by a viscosity and b soil moisture content (Gerstl

et al.

1994

)

field capacity. No kerosene flow was observed in the clay soils from oven-dried to

field capacity moisture contents.

These behaviors can be explained as follows. First, the decrease in kerosene

conductivity in sand is caused by a mechanically induced change in the original

porosity, which occurs during leaching to reach a field capacity moisture content.

In the loamy soils, the porosity of the system is hardly affected, as the moisture

content increases toward field capacity, and instead, there is a reduced resistance to

the flow of kerosene. This phenomenon flow can be attributed to the Yuster effect

(Rose

1993

), which is a lubrication effect occurring when a thin layer of water

coats the surface, thus reducing the resistance to flow and preventing interaction

between the solid phase and kerosene molecules. When the loamy soil is oven-

dried, kerosene infiltrating into the soil is adsorbed on the pore surfaces, creating a

wall effect that retards movement by formation of a viscous layer. The kerosene

conductivity is not changed in clay soils, regardless of the moisture content. Ini-

tially, when the soil humidity ranges between oven-dried and air-dried, kerosene

adsorption on the surface of the solid material controls its flow, and subsequent

pores plugging by water impede the kerosene flow.

Retention in Porous Media As NAPL migrates through the subsurface, some

of it becomes entrapped according to its retention capacity. In addition, NAPL

constituents may become redistributed in the gaseous phase.

The extent of kerosene trapping was determined quantitatively in a series of

laboratory and outdoor experiments with Swedish soils (Jarsjo et al.

1994

),

yielding an empirical equation for the kerosene residual content as a function of

soil composition: