Environmental Engineering Reference

In-Depth Information

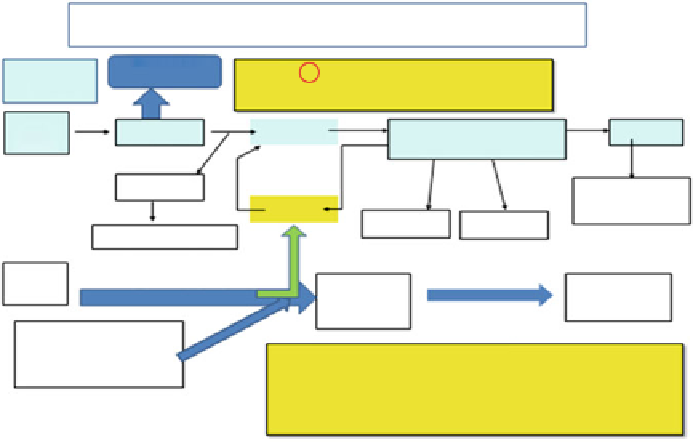

Strategic new Si technology

-Two approaches to innovative Si technology

Metallurgical

Purification

Siemens

Process

1

More than Siemens

CVD Yield: 25

→ > 80 %

Cz of Fz

C

SiO

2

{Rock}

[ SiHCl

3

]

SEG(poly)-Si

(Purity > 10 N)

MG-Si

SC-Si

CVD

Purity 98%

SiH

4

Slice

Cast

+ Slice

H

2

Shot

sc-Si

solar cell

[

SiCI

4

]

Plasma CVD

Ingot

Ribbon

Thin film solar cell

CL

2

Purification

(B, P < 1 ppm)

SiO2

(sand)

+

Up-grade

SOG-Si

Purified

power

Direct reduction

Carbon

or

Activated hydrogen

Beyond Siemens

Powder purification in advance

Drastic energy saving by skipping CVD (costdown)

Product only for PV

2

Fig. 9

Strategic new Si technology including two innovative approaches

precipitate SiO

2

. This process could not be

applied to desert sand directly due to low solubil-

ity of the sand which is composed primarily of

crystalline silica. We found that this problem

could be solved by applying the ball milling to

the sand which had been gravimetrically sepa-

rated and rinsed with HCl in advance. Thus, we

could merge the purifi cation process of desert

sand with that of amorphous silica as shown in

Fig.

11

. ICP-OES analysis verifi ed sub-ppm lev-

els of boron (B) and phosphorus (P) impurities in

the silica purifi ed from Sahara sand at Hassi

Messaoud location in Algeria. Metallic impuri-

ties are known to be segregated effectively by the

unidirectional solidifi cation process.

than 12 % was achieved (NEDO

1987

). It must

be noted that this effi ciency is higher than the

effi ciencies of conventional thin-fi lm solar cells.

Hence, we can get Si solar cells with reasonably

high effi ciency and durability once we have

SOG-Si. By omitting the energy-consuming

CVD process (~100 kWh/kg-Si) in the conven-

tional Siemens process (Figs.

9

and

10

), drastic

energy saving and production cost reduction

should be achieved.

6

Conclusions

and Recommendations

The importance of access to clean energy cannot

be overstated. Research, development and dem-

onstration (RD and D) are the foundation for

progress and change towards sustainable energy

systems throughout the world to protect the

global life-supporting systems and reduce the

risk of geopolitical confl icts over fossil fuel

resources which are quickly depleting materials.

We need more electricity from RE and more

investment and initiative to make solar energy

cost-effective and competitive. There are good

examples of business initiatives to enhance

5.3

Direct Reduction of Purifi ed

Silica to Silicon

In the 1980s, NEDO-supported Nippon sheet

glass/JFE Co. joint project, which reported that

purifi ed silica reduction with carbon powder in

an arc furnace using graphite shafts to feed pel-

leted SiO

2

and C to give 6 nine grade SOG-Si.

This Si was used to fabricate polycrystalline Si

solar cells. Energy conversion effi ciencies higher

Search WWH ::

Custom Search