Environmental Engineering Reference

In-Depth Information

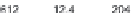

TABLE 6.15

Value.of.Technological.Parameters

Length

delaminating,

mm,C

CracksNumber,n

Parameter,C*n

Strain,

Δε

2

,%

6

1

6

2.4

12

2

24

4.9

18

3

54

7.3

24

4

96

9.8

30

5

150

12.4

CORRELATION BETWEEN TEMPERATURE GRADIENT AND STRAIN PROPAGATION

700

600

500

400

300

200

100

0

Column A

Column B

Column C

Column D

1

2

3

4

5

STRAIN PROPAGATION IN DIFFERENT LAYERS, %

FIGURE 6.7

Measured.correlation.between.temperature.gradient.and.strain.propagation.

6.3.4

Fatigue Strength Improvement

Figure 6.8.shows.the.simultaneous.injection.of.a.healing.agent.and.catalyst.

into.the.test.package.during.stress.testing..Injection.occurred.when.a.temper-

ature.gauge.indicated.to.the.injection.pumps.when.the.surface.temperature.

of.the.package.increased..The.healing.agent.and.solid.catalyst.are.dispersed.

irst.

27

.Valves.control.the.four.pumps.indicate.in.Figure 6.8.

6.3.5

Conclusions

.

1.. Laser.light,.detected.by.imbedded.sensors,.is.a.good.measure.of.the.

formation.of.delaminating.cracks.during.fatigue.testing.

.

2.. An.infrared.radiation.camera.accurately.measures.the.surface.tem-

perature.of.test.objects.during.fatigue.testing.

.

3.. Surface.temperature.is.a.good.predictor.of.fatigue.strength.as.mea-

sured.by.fatigue.testing.

.

4.. Injecting. a. healing. agent. and. a. solid. catalyst. can. increase. fatigue.

strength.by.up.to.30.percent.

Search WWH ::

Custom Search