Geology Reference

In-Depth Information

Table 16.4

Overburden thickness and gravel thickness measurements

on various Kwango targets

Primary

target area

(km

2

)

Gravel

thickness

(m)

Overburden

thickness

(m)

Strip ratio

(waste:

ore)

Target

K97

10.6

0.22

9.3

42

K82

5.5

0.32

10.8

34

Second splay

12.1

0.48

10.8

23

K64

6.6

0.18

11.6

64

Kitangu K56N

4.0

0.24

10.7

45

Bomba K56S

9.2

0.18

9.4

52

Flat 13/14

7.2

0.35

6.9

20

First Splay

4.5

0.6

4.1

7

Hilltop Pitting

0.14

3.6

26

Total

150

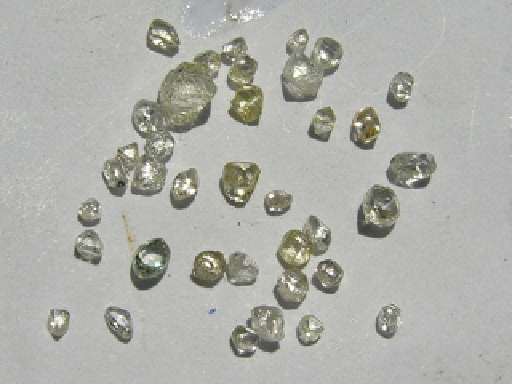

Fig. 16.20

Typical diamonds from the

'

international

'

Kwango below

the Falls with a high percentage colourless stones, many fragments and

a significant degree of abrasion

Table 16.5

Grade required to Break-Even (cpht) for Second Splay

target (strip ratio of 23:1)

Diamond value

$50/ct

Mining cost

(waste and ore)

16.5.5 Economic Modelling

$80/ct

$200/ct

$300/ct

$3/ton

141 cpht

88 cpht

35 cpht

24 cpht

$6/ton

282 cpht

176 cpht

71 cpht

47 cpht

In order to assess the economics of mining alluvial diamonds

along the Kwango, strip ratios, diamond values and grades

had to be evaluated against mining costs, which were

anticipated to be significantly higher than those for similar

sized placer operations in South Africa. This was due to lack

of infrastructure and the remoteness of the study area,

combined with legal and administrative complexities of

operating in the DRC.

Through its pitting and drilling program on the Kwango,

BRC was able to quantify with a reasonable level of confi-

dence the strip ratios (i.e. ratio of overburden to gravel

thickness) to be expected on various targets within its study

area. With the exception of First splay, which occurs at the

point where the Kwango River valley widens, strip ratios are

greater than 20 for the 8 targets on which sufficient over-

burden and gravel thickness data was collected (Table

16.4

).

Furthermore, the diamond size frequency distribution

analysis carried out by BRC within its Kwango project

area suggests stone sizes were generally small, with an

average stone size of 0.103 cts/stn (Table

16.2

). As a result,

it was estimated that diamond parcels from this area would

fetch low prices, in the range of US$50/ct to US$75/ct

(Maurice Barker, 2007, personal communication).

In order to establish diamond grades on the various

targets a trial mining campaign was contemplated by BRC,

utilizing a small mobile 5 tph DMS plant. Before proceeding

with this campaign, however, a break-even analysis was

carried out on the 9 targets for which strip ratios had been

sufficiently well established, in an attempt to determine the

spectrum of diamond grades required to recoup mining

costs, given a range of (i) Mining Costs ($/ton) and (ii)

$10/ton

470 cpht

294 cpht

118 cpht

78 cpht

Diamond Values ($/ct). Break-Even grade, expressed in

carats per hundred tonnes, is defined as the grade at which

revenues from mining operations pay for the costs of the

operations, thus generating no profits or losses. Break-even

grade was calculated using the following formula:

ðÞ

Diamond Value

Mining cost

$

=

t

Break

Even Grade cpht

ð

Þ ¼

‐

ð

$

=

ct

Þ

ð

Overburden Thickness

þ

Gravel Thickness

Þ

100

Gravel Thickness

Table

16.5

and Fig.

16.21

summarize results of the break-

even analysis for the Second Splay, with an overall strip

ratio of 23:1 (waste to ore).

These results suggest that diamond grades in excess of

150 cpht would be required to break-even on the Second

Splay given that:

1. Mining costs for a mechanized placer mining operation

on the Kwango in 2007 were anticipated to be in excess of

$4/ton.

2. Diamonds were estimated to be valued at $50 to $75/ct.

Had the analysis also taken into account Processing Costs

for

running a DMS plant

(

$6/ton) and General and

Administrative Costs (

$1/ton), the grades required to

break-even would have been even higher, likely in excess

of 400 cpht. The probability of attaining such grades, based

on historical and contemporary data was deemed to be low.

Search WWH ::

Custom Search