Environmental Engineering Reference

In-Depth Information

1

2

5

6

4

3

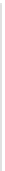

Fig. 3.9

Schematic of the quartz flow reactor

1) Inlet 1; 2) Inlet 2; 3) Outlet; 4) Air cooling; 5) Quartz flow reactor; 6) Preheat channels

The total flow rate of all reactants, including O

3

and the simulated flue gas,

were fixed at 1000 mL/min. The residence time in the center tube ranged from

0.049 to 0.089 s and varied with the temperature calculated by 33.3

K

/

T

s, while

that in the washing tower was approximately 9.7 s. The initial component

concentrations used in the test were 215±10 ppm NO, 220±10 ppm SO

2

,

4000±200 ppm O

3

, and 50±0.5 μg/m

3

Hg, respectively.

3.3.2 Oxidation Mechanism Between O

3

and NO

In most practical flue gas, NO is the predominant nitrogen species of NO

x

. Unlike

NO, the other species such as NO

2

, NO

3

, and N

2

O

5

are highly soluble in water,

which can be captured in a SO

2

removal equipment, such as the WFGD system.

Therefore, NO oxidation is the first step for the simultaneous removal of SO

2

and

NO

x

. When O

3

is injected into the center tube, NO in the flue gas can be oxidized

into NO

2

, NO

3

, and N

2

O

5

, as shown in the following reactions:

Search WWH ::

Custom Search