Environmental Engineering Reference

In-Depth Information

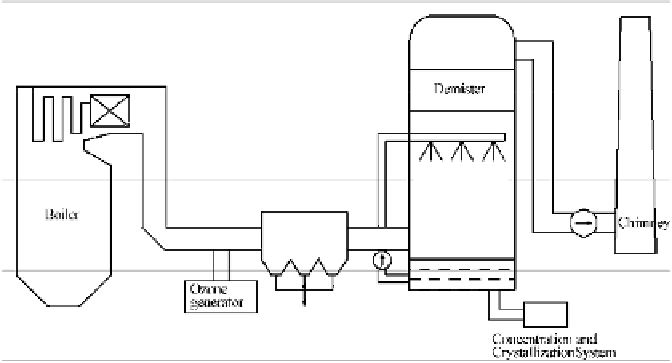

Incorporated with Ozone Oxidization and Alkali Solution Adsorption

integrated with the absorbability of acid gas of SO

2

, HCl, and HF in the alkali

solution scrubber. Afterwards, the produced sulfates and nitrates can be extracted

and concentrated in the crystallization system and then be sold as industrial raw

materials. Meanwhile, Hg

2+

in the solution can transform into the steady HgS

precipitation through the treatment of H

2

S gas, thereby avoiding secondary

pollution.

Washing

tower

Electrostatic

precipitator

Concentration and

crystallization system

Fig. 5.1

Schematic diagram of the simultaneous removal of multi-pollutants by ozone oxidation

Although here the sole denitration retrofit cost is relatively higher than any

other NO

x

reduction technologies (typically SCR and SNCR), the present

multi-pollutants removal technology focuses on the most effective removal of NO

x

,

SO

2

, Hg

0

, HCl, and HF, thereby being acknowledged as a cost-effective, near-zero

pollutant emission, co-product reutilization alternative to the development of new

multi-pollutants removal technologies. According to our experimental results, the

removal efficiencies are over 90% for NO

x

, above 99% for SO

2

, about 95% for Hg,

and over 95% for both HCl and HF. Here the NO

x

removal efficiency is also

related with combustion control in the furnace. NO

x

should be first lowered

through approaches such as low-NO

x

burners, air-staging combustion, and fuel

reburning. For example, with the initial NO

x

concentration in the furnace lowered

by about 150 - 200 ppm, the original NO

x

emissions of 800 mg/m

3

(at 6% O

2

) can

be lowered to 300 - 400 mg/m

3

(at 6% O

2

). Subsequently, another 100 - 150 ppm

reduction extent in the remaining NO

x

is achieved through ozone oxidation in flue

gas, finally resulting in a total NO

x

removal efficiency of 93.7%.

Search WWH ::

Custom Search