Environmental Engineering Reference

In-Depth Information

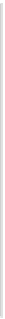

Table 9.2

Breakdown of Different Classes of Plastics in MSW and

their Recovery

Source: From EPA (2011).

Plastics Waste

generation

short tons

Percent waste

generation

(%)

Percent

recovery of

waste (%)

Recovery

rate (%)

HDPE 5,450,000

17.6

22.4

10.5

LDPE/

LLDPE

7,430,000

23.9

16.5

5.7

PET

3,980,000

12.8

30.6

19.6

PP

7,530,000

24.3

1.6

0.5

PS

2,060,000

6.6

0.8

1.0

PVC

910,000

2.9

0

0

Another recent waste management trend is to export waste, often sorted

plastic waste, for reprocessing. The EU countries for instance export waste

plastics (mainly polyethylene (PE) and PP) to member countries (mostly

Germany and France) as well as to Asia (mostly China) for reprocessing.

The different recovery options available for plastics waste might be

summarized as follows:

9.1.1 Material Recycling

The products are recovered from the MSW stream via curbside collection,

separated/sortedatMRFs,andthencleanedandgroundintochipsatplastic

reclaiming facilities to be remelted into recycled resin pellets. The recycled

resin is used, mixed with virgin plastics, in the fabrication of plastic

products. Mechanical recycling works best when applied to

source-separated streams of waste plastics products.

9.1.2 Feedstock Recovery

Waste plastic is changed by heat or chemical agents into chemicals that

might be used in the production of new polymers or as general chemical

feedstocks (Al-Salem et al., 2010). Monomer recovery works well with

source-separated plastics whereas general feedstock recovery is better

suited for mixed plastic waste.