Environmental Engineering Reference

In-Depth Information

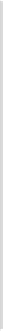

Table 5.1

Density, Modulus, and Strength of Materials Used in

Automobiles

Source: Based on Cheah (2010).

Material

Density

(g/cm

3

)

Modulus

(GPa)

Tensile

strength

(MPa)

Embodied

energy (MJ/kg)

Mild steel

7.86

200

300

32

High-strength

steel

7.87

205

483

32

Aluminum

2.71

70

295

199

Magnesium 1.77

45

228

350

75 GRC

a

Polymer

composite

1.57

190

810

150 CRC

b

a

Glass-reinforced composite.

b

Carbon-fiber-reinforced composite.

In a recent study, the steel assist step in Chevrolet TrailBlazer/GMC Envoy

was replaced by a functionally equivalent (slightly larger) but 51% lighter

plasticone(PEInternationalInc.,2012).Theimpactofthissubstitutionwas

studied over the vehicle lifetime using standard LCA methods. This single

replacement is estimated to have saved 2.7 million gallons of fuel over the

lifetimes of the full fleet of the 148,658 (2007 model year) vehicles. Fuel

savings also result in avoided emission of carbon into the atmosphere. All

environmental attributes did not improve as a result of the change: the

acidification potential was higher for the plastic part compared to the metal

step. Cost savings from the substitution of metals are readily apparent when

commercial fleets of vehicles are considered. In a redesigned prototype

replaced with ABS plastic panels. Fuel economy gained from this change

was shown to be about 40%. The savings in energy and emission accrued

on switching to the lighter functionally comparable panel is obviously very

significant.

National Highways Traffic Safety Administration (NHTSA) reported an

interesting study (NHTSA, 2012) on material substitution from steel to