Environmental Engineering Reference

In-Depth Information

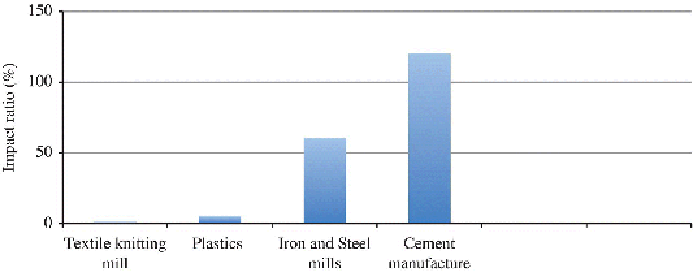

Figure 4.11

Total direct environmental damage as a percentage of revenue

for several selected industries.

Source: Based on data from Trucost Plc. (2013).

However, as already alluded to in the introduction, the plastics industry

constitutesonlyaverysmallfractionoftotalindustry.Aswiththeassociated

energy costs, the question is if the environmental “cost” is excessive

4.5 PLASTICS ADDITIVES

To ensure the desired properties and for facile processing of the material,

additives are mixed in with the resin during compounding. Some of these

are inert fillers or recycled plastic used to bring down the cost of the

manufactured product, while others are used to ensure specific

functionalities.

Table 4.8

indicates the ranges of levels at which these

additives are typically used. The exact level depends on the grade of resin as

well as on the properties demanded of the compound. The main classes of

additives in plastics are shown in

Figure 4.12

:

a. Stabilizers that protect plastic from thermal degradation during

processing and light-induced thermo-oxidative and biological damage

during use

b. Reinforcing fillers and plasticizers that improve the mechanical

properties such as the modulus of plastic material, to match the service

requirements

c. Processing aids that make the processing of the material easier