Environmental Engineering Reference

In-Depth Information

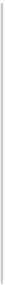

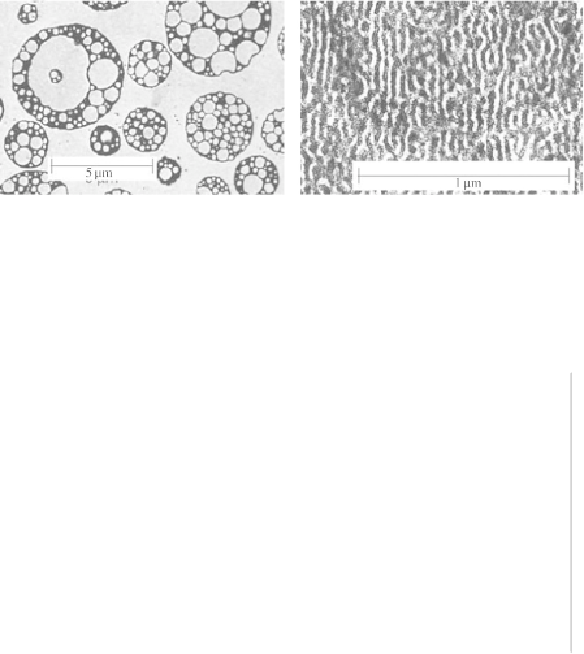

Figure 3.14

Left

: An electron micrograph of a thin section of HIPS

showing the rubber microdomains.

Right

: An electron micrograph of a thin

section of SBR copolymer.

Source: Courtesy of Styrolutions, Styrolux, BASF.

Table 3.5

Properties of Different Grades of Polystyrene

HIPS

a

SPS

b

GPSS

Specific gravity

1.04

1.04

1.02

Melt flow (g/10 min) 1-20 2-15

Tensile strength (psi) 5-7 3-7 1.04

Flexural strengths (psi) × 1000 17-15.0 2-8 11.6

Tensile elongation to break (%) 2-3 15-65 30

Flexural modulus (psi) × 1000 450-500 270-420 465

Vicat softening temperature (°F) 195-228 185-225

The variety of PS that is ubiquitous is expanded polystyrene (EPS) or PS

foam commonly used in cups and food service applications. The expanded

grade is manufactured as beads of PS containing pentane, a liquid

hydrocarbon at room temperature. When the beads are heated in steam

(or “expanded”), the pentane volatilizes to expand the beads into a

thermoplastic foam. These foam beads are subsequently packed into molds

and fused by heat into the shape desired. The EPS can also be extruded into

sheets and thermoformed into products such as meat trays and plates. EPS

has good thermal insulation and shock-absorbing properties.