Environmental Engineering Reference

In-Depth Information

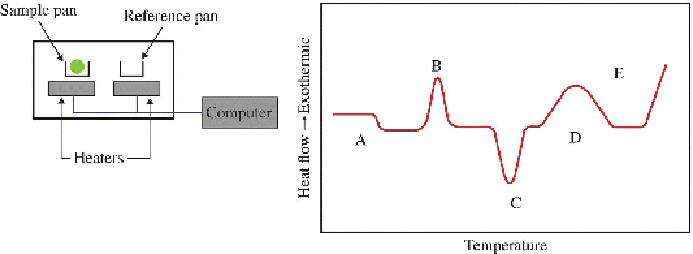

heat flow to each pan at a given temperature to be monitored separately.

The plastic sample to be analyzed is placed in one of the pans; the difference

in heat flow needed to maintain both pans at the same temperature is

accurately recorded during the heating process. It is essentially a

measurement of the heat capacity of the sample as a function of

temperature. The value of Δ

T

(°C) plotted as a function of temperature

T

(°C) yields a DSC trace that reflects the thermal characteristics of the

material. A generalized DSC trace of a semicrystalline polymer is shown

in

Figure 3.11

showing the features associated with changes on heating the

plastic sample.

Figure 3.11

Left

: Basic features of a DSC instrument.

Right

: A generalized

DSC tracing.

The DSC curve shows the crystallization exotherm (B) and a melting

endotherm (C) followed by an exothermic decomposition of the plastic (E)

at higher temperatures (Bruns and Ezekoye, 2014). At a lower temperature,

a first-order step change in the curve (A) is apparent and signifies the Tg

of the material (Feng et al., 2013), and in some instances, a transition that

signifies cross-linking (D) is also observed.

The melting transitions for blends of PP are shown in

Figure 3.12

. The area

under the DSC tracing of differential heat flow (

dH

/

dT

) is the enthalpy

change associated with the transitions. This is the sum of heat capacity

and the heat flow needed to accommodate the physical/chemical changes

undergone by the plastic material: