Environmental Engineering Reference

In-Depth Information

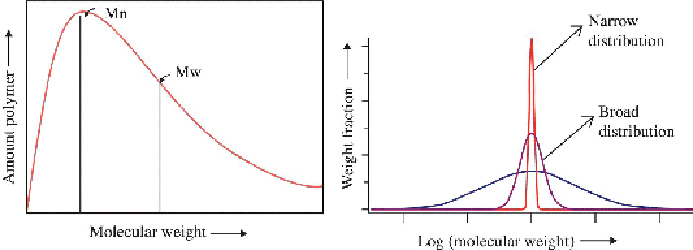

Figure 3.4

Left

: Schematic drawing of the molecular weight distribution

of a polymer indicating the two averages

Mn

and

Mw

.

Right

: Schematic

diagram of the molecular weight distribution for polymer samples with low

and high PDI.

The readout obtained is a distribution of weight fractions (

Fig. 3.4

,

left

). The

right-handendofthedistribution hasshort-chainmoleculesthatcanhardly

be called polymer, and the left-hand end of it has the longer-chain high

polymermoleculesinthemix.Thetwoaverages,

Mn

and

Mw

,areindicated

with lines; note that always

Mw

>

Mn

and (

Mw

/

Mn

) is the polydispersity

index (PDI) of the chains. The smaller this value, the narrower will be the

distribution of chain lengths. If all the molecules in the polymer had exactly

the same chain length or molecular weight, then,

Mw

=

Mn

and PDI = 1.

Polymers made by chain reaction generally have values of PDI ranging from

2 to 20, while those made by step reaction have narrower distributions with

P.I. ~ 2.0.

AveragemolecularweightandPDIarebothimportantastheydeterminethe

properties of the polymer. The mechanical properties of plastics that make

them so useful depend on the material having a high molecular weight. As

theaveragemolecularweightisincreased,mechanicalpropertiesliketensile

strength, stiffness, and hardness will also increase. As

Mn

increases, the

melting range as well as the viscosity of the melt also similarly increases.

The higher the

Mn

, the better will be the mechanical properties, but more

difficult will be the processing (which involves molten plastic) due to the

high melt viscosity. Depending on the intended application, usually, a

compromise has to be made between high

Mn

of the plastic and the ease

of processing. At very high or infinite molecular weight, a given property, P,