Chemistry Reference

In-Depth Information

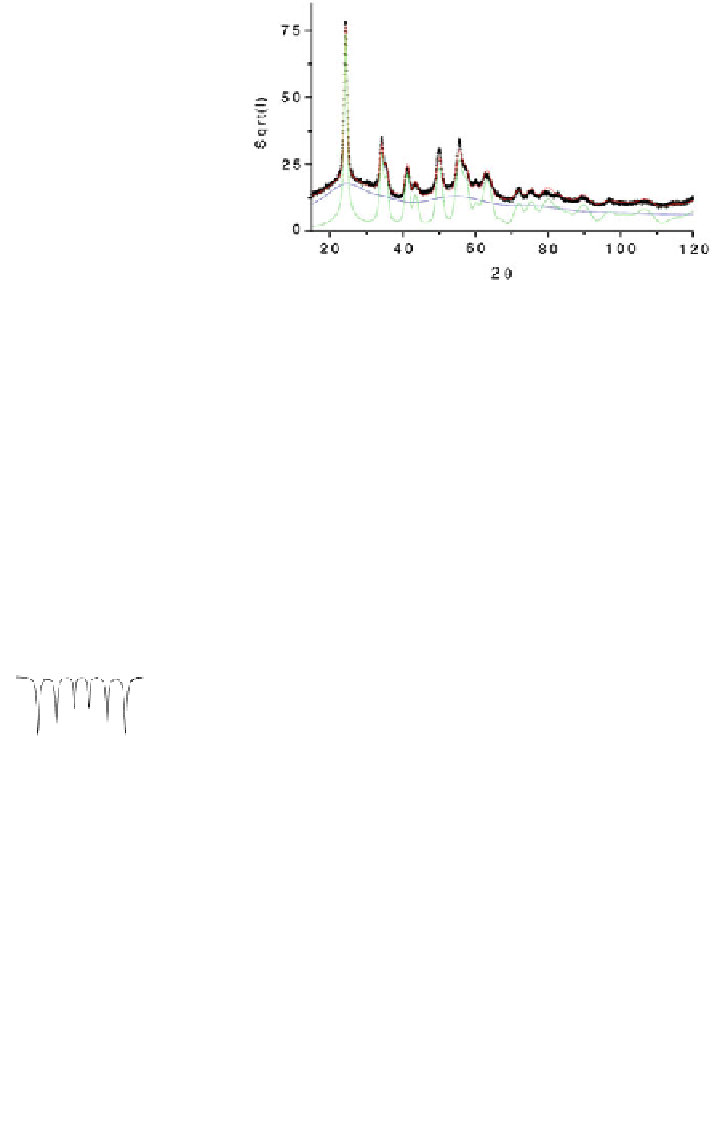

Fig. 4.22 Typical X-ray

pattern of milled FeF

3

and its

decomposition into two

components attributed to

crystalline grains and grain

boundaries [

165

]

part of Bragg peaks. The X-ray diffraction pattern modelling gave successfully rise to the

presence of two main components with broadened peaks, the proportions of which are

rather equivalent. The first component with well resolved peaks is attributed to rhom-

bohedral nanocrystalline and spherical grains with a size of about 15 nm diameter while

the second component corresponding to the low part is characteristics of structural

coherent diffraction domain of about 0.4 nm (equivalent to the size of an FeF

6

octahedral

unit): it is thus assigned to grain boundaries resulting from a packing of octahedral units.

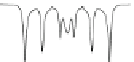

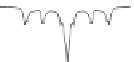

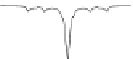

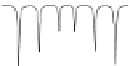

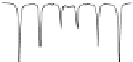

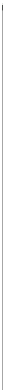

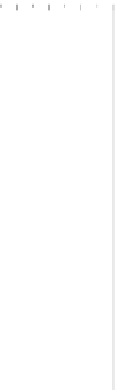

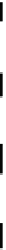

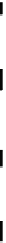

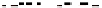

Series of Mössbauer spectra were recorded for different grinding times and

grinding energy at different temperatures and in presence of external magnetic

field. The modelling does take into account simultaneously the corresponding

hyperfine structures [

166

]. Examples of spectra and corresponding hyperfine field

distributions are given in Fig.

4.23

recorded at 300 and 4.2 K on r-FeF

3

in the

100

100

80

60

50

40

20

60

0

0

30

40

50

0

10

20

30

40

50

2,0

50

25

1,0

25

60

0

0

0

10

20

30

40

0 0 0 0

30

40

50

50

50

2

25

25

1

0

0

60

0

0

10

20

30

40

0 0 0 0

30

40

50

50

50

2

25

1

25

0

0

0

0

10

20

30

40

0 0 0 0

30

40

50

60

50

2

50

25

1

25

0

0

60

0

0

10

20

30

40

0 0 0 0

30

40

50

-10

-5

0

5

10

-12

-6

0

6

12

mm/s

mm/s

Fig. 4.23

Mössbauer

spectra

recorded

at

300 K

(left)

and

4.2 K

(right)

on

as-prepared

crystalline FeF

3

(top) and ground for 0.25, 1, 8 and 16 h (top to bottom)[

166

]