Chemistry Reference

In-Depth Information

4.8 Milled Fe Nanostructured Powders

Nanostructured Fe powders were also elaborated from microcrystalline Fe pow-

ders by means of high energy ball milling using planetary ball under Ar atmo-

sphere [

159

]. Their reproducibility is well achieved providing similar milling

conditions: ball to powder weight ratio, milling speed, milling time, milling

atmosphere, nature of balls and mill vial while some of them have to be considered

to prevent from contamination and oxidation of metallic powders.

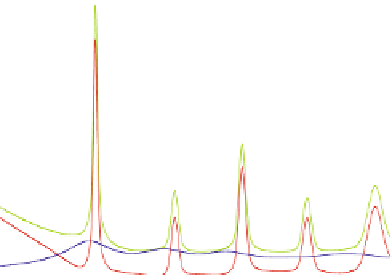

High statistics X-ray patterns recorded on milled Fe powders for different times

allow to model the nanocrystalline structure including the size and morphology of

coherent diffraction domain and their relative proportion, providing an additive

component is introduced to describe the low part of Bragg peaks. The experi-

mental pattern is compared in Fig.

4.8

to the theoretical one obtained by means of

Maud procedure which is based on the Rietveld method combined with Fourier

analysis. In addition, the mean morphology of the coherent diffraction domain

illustrated in inset of Fig.

4.18

suggests that the nanocrystalline grains behave

10-12 nm pseudo-cubes, favouring a dense packing through thin grain boundaries

[

159

]. In this hypothesis, the thickness of the grain boundary can be roughly

estimated at about 0.8 nm, i.e. 2-3 atomic layers, smaller than those observed

previously in the case of Fe clusters generated by inert gas condensation and in situ

consolidated [

158

].

On the contrary, Mössbauer spectrometry does not provide any further infor-

mation except that the presence of sextet typical of bcc-Fe structure remains

milling time independent, as observed in Fig.

4.19

. Low temperature Mössbauer

spectra confirm such a tendency as the hyperfine structure resulting from a single

magnetic sextet is not affected. At this stage, one does consider that the grain

boundaries which do not contribute to the hyperfine structure are only weakly

disordered and quite narrow. High temperature spectra could eventually cause a

splitting of the hyperfine structure but they were not recorded because of any

Fig. 4.18 32 h Fe milled

powder X-ray pattern fitted

with two components and

morphology of crystalline

grains [

159

]

50

grain

GB

40

30

20

10

0

20

40

60

80

100

120

2*Theta