Biomedical Engineering Reference

In-Depth Information

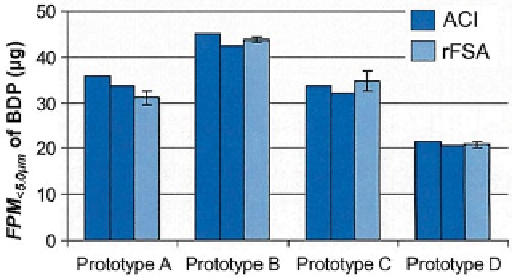

Fig. 10.17

Comparison of values of

FPM

<5.0μm

achieved by aerosolizing BDP (100

μ

g per actua-

tion/50

L metered volume) with novel prototype actuators A-D: series 1 and 2 refers to the two

ACI measurements (

n

= 2) shown separately: series 3 refers to the rFSA measurements (

n

= 3), in

which mean ± SD is illustrated for group (

From

[

28

]—

used with permission

)

μ

In the second phase of their investigation, four prototype actuators were assessed

using a standard procedure (

n

= 2; ACI) and rFSA method (

n

= 3) in order to deter-

mine the screening capability of the rapid method. The trend in

FPM

<5.0μm

observed

between prototypes A-D was found to be independent of the impactor method, with

prototype B delivering the optimal dose (Fig.

10.17

).

Keegan and Lewis observed that their rFSA method reduced the time taken to

obtain replicate ACI measurements by 50%. This time saving was in addition to

other reported benefits such as reduced solvent consumption, analysis time, and

data processing. They concluded that their AIM-based methodology represents a

sufficiently precise method for determining key particle distribution metrics such as

FPM

<5.0μm

for the purpose of screening and design optimization studies.

In their second investigation [

29

], Keegan and Lewis turned their attention to the

use of their FSA as a tool for the rapid screening of solution pMDIs containing

increasing concentrations of ethanol. The effect of adding 1.3% w/v glycerol was

also investigated with the preparation containing 13% ethanol. The general test pro-

cedure used by Keegan and Lewis was similar to that for the full FSA method

described in their first study [

28

].

An additional spacing stage was included above the first impaction stage in the

FSA, as recommended by Mitchell et al

.

(see Fig.

10.4

) [

20

] for some measure-

ments. In this modified FSA (mFSA) configuration, more time was allowed for

ethanol to evaporate, with the aim of achieving closer agreement with full-resolution

benchmark ACI measurements for these MDI products. However, this annular

spacer stage differed from the approach adopted by Mitchell et al

.

, in that it con-

sisted of a metal ring without the nozzle plate (Fig.

10.18

).

The MDIs, again containing BDP as API (100

L metered

volume), were manufactured containing 8%, 13%, and 26% w/w ethanol in HFA134a

propellant. Each MDI was equipped with the same actuator as used in their first

study. Values of

CPM

>5.0μm

,

FPM

<5.0μm

, and

EPM

<1.0μm

obtained from each of the

μ

g per actuation/50

μ

Search WWH ::

Custom Search