Environmental Engineering Reference

In-Depth Information

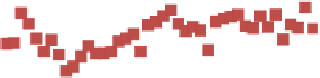

CODin (mg/L)

CODout (mg/L)

12000

10000

8000

6000

4000

2000

0

1

11

21

31

41

51

61

71

Days

Fig. 4

CODproileoverthetrialperiod

Upflow velocity is regarded as one of the key parameter significantly affecting

microbial ecology and characteristics of UASBR. It also helps in flushing the haz-

ardous gases thereby keeping the system in healthy condition. The optimum upflow

velocity for the wastewater and the system under study was found to be 0.5 m/h. In

ordertomaintainthedesiredOLRanduplowvelocity,thefeedtoUASBRis4-5

times of the influent and hence the same was recycled back to buffer tank/UASBR

feed tank. This also helps in minimizing the toxicity and shock load to UASBR.

TheCODreductionintheinitialphaseofthestartupwasonthehighersidedue

tohigherpercentageofCODfromthejaggerywhichiseasilybiodegradable.COD

reduction stabilized to 47-50 % (Fig.

4

) which was desired by the manufacturing

facility.CODreductionof90-95%wasachievedwiththecombinationofanaero-

bic followed by aerobic reactor, whereas only 85-90 % of COD reduction was

observed with two-stage aerobic reactor. This may be due to presence of facultative

micro organisms present in the reactor which releases certain enzymes which are

able to convert high molecular aliphatic/aromatic compounds into smaller linear

chainmoleculeswhichareeasilybiodegradable(SinghandChoubey

2012

). Based

on pilot plant observations, full scale plant was designed.

Cost Economics

The manufacturing unit was planning to increase the production of IX resins, which

will lead to increase in flow as well as organic load to the ETP. The expansion of

the manufacturing facility will lead to increase in the flow to ETP from 180 m

3

/day

to 240 m

3

/daywithmarginalornochangeintheCODandBOD.Acostcompari-

son of UASBR against installation of an aerobic reactor was carried out which is

presented in Table

2

.

Search WWH ::

Custom Search