Environmental Engineering Reference

In-Depth Information

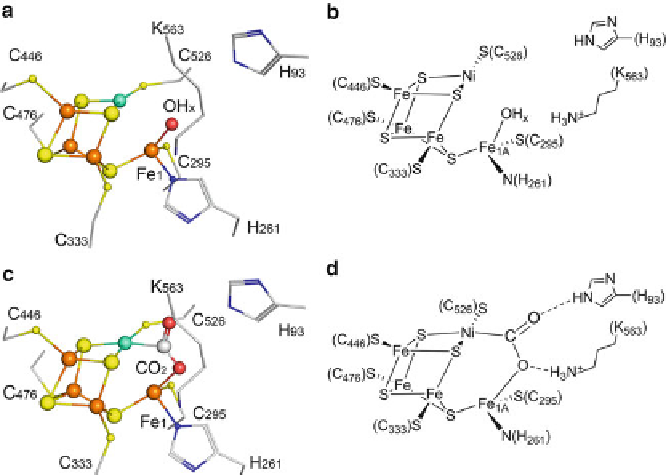

Figure 7 Structure of cluster C from CODH II

Ch

.(a) Ball-and-stick model of active site cluster C

with conserved ligands in the second coordination sphere in the -320 mV state. (b) Schematic

drawing of the [Ni4Fe4S-OH

x

] cluster C. (c) [Ni4Fe4S(CO

2

)] cluster observed in the -600 mV

+CO

2

state. (d) Schematic view of cluster C with bound CO

2

. The secondary positions of Fe

1

(Fe

1B

) and Cys

295

were omitted in the schematic drawings for clarity.

approximately 133

. The Ni,Fe-bound CO

2

is additionally stabilized by hydrogen

bonds to a lysine and a histidine residue [

94

].

2.2.3 Pathways and Channels Involved in Catalysis

The high turnover number of Ni,Fe-CODHs demand a rapid and guided channeling

system for substrates and products. CO and CO

2

, water as well as protons and

electrons must be able to rapidly reach and egress from the active site.

Four different paths reach out from cluster C: a gas channel (CO/CO

2

), a proton

relay, a water network, and an electron transfer chain (Figure

8

). Monofunctional

Ni,Fe-CODHs employ two sets of gas channels. One is conserved and coincides with

the tunnel that is connecting cluster C of Ni,Fe-CODH and the active site cluster A of

ACS in bifunctional Ni,Fe-CODHs (Section

2.3

). The other channel is unique to

monofunctional Ni,Fe-CODHs and is directed to the solvent, allowing rapid progress

and egress of CO/CO

2

from the active site towards the solvent [

95

]. Recently,

molecular dynamics and density functional theory calculations pointed to an addi-

tional, dynamically formed gas channel, through which CO

2

may diffuse from the

solvent to cluster C of CODH/ACS [

96

]. Simulations imply, that upon CO

2

reduction

the extended hydrogen network prohibits CO leakage through the gas channel.

Search WWH ::

Custom Search