Information Technology Reference

In-Depth Information

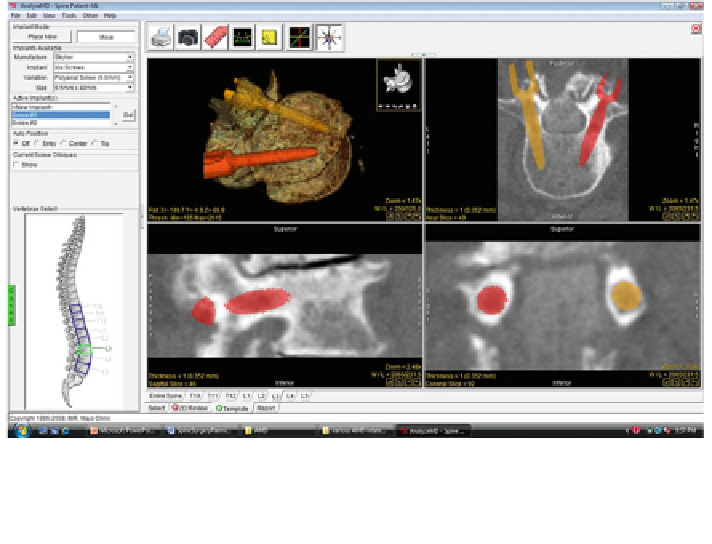

Fig. 3 Pedicle screw template placement. Screw templates are placed interactively into the image

data with the mouse. Each template corresponds to a particular prosthetic implant manufacturer.

The screws are evaluated in the orthogonal images and rendering to ensure that the screws are of

the appropriate length and thickness

required if the spinous process does not line up parallel to the y-axis in that view.

The realignment is also shown in Fig.

2

.

In the second step, digital templates of screws are selected and inserted into the

3D data. During the selection step, the appropriate type of pedicle screw is chosen

and a size is selected. The template is then placed into the axial image that includes

the widest portion of the pedicle. The virtual pedicle screw can now be translated or

rotated interactively in any of the three orthogonal views to achieve optimal

placement within the vertebra, as shown in Fig.

3

. Exact dimensions and angle

placement for each screw placed is automatically recorded for use in the

nal

report, which is the last step in the 3D spine surgery planning process. The report

provides a list of each screw templated, including the vertebra in which they are

placed, the manufacturer of the screw, the dimensions of the implant, and the

precise location within the vertebral body based on the axial and sagittal angles. In

addition to the implant list, a number of images are automatically generated and

added to the report for visual veri

cation.

3.2.3 Fastening Strength Formulation

According to strength of materials principles and theories of failure, each screw

withstands a maximum force before it can be torn away from the material after its

insertion. The holding power of a typical screw depends on the dimensions of the