Biomedical Engineering Reference

In-Depth Information

of metal ion solutions to CNXL suspension resulted in loosely packed precipitates,

which were separated from the liquid by centrifugation. The CNXL films with metal

ions incorporated were dried at room temperature in air. CNXL itself showed some

surface oxidation, which had a FT-IR carbonyl stretching band at 1720 cm

−

1

,which

was generated during the hydrolytic preparation. After adding metal ions to the CNXL,

the carbonyl band was decreased due to the interaction between the carboxyl groups and

metal ions. Thermal treatment at 160-200

◦

C initiates the redox reaction on the composite

film, and the metal ions are reduced by the CNXL surface while some hydroxyl groups

on the CNXL were oxidized into carboxyl group again, which can be seen from the

reappearance of the peak around 1720 cm

−

1

(50).

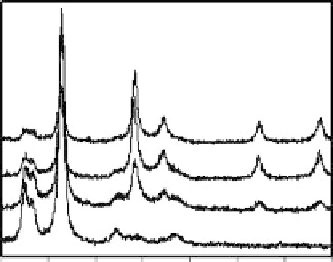

Figure 12.8 shows XRD traces of reduced Ag nanoparticles on the CNXL. As-prepared

Ag(I)/CNXL composite film does not contain any crystalline silver even after several

days at room temperature, indicating that room light is not enough to reduce silver (I)

ions at the temperature. The composite film thermally treated at

150

◦

C did not show

any crystalline silver peaks because the elemental silver reduced by CNXL surface did

not nucleate to grow into nanocrystals, but silver nanocrystals were big enough to be

observed at 160

◦

C. After the low Ag loading samples (3.1 wt%) were treated at 200

◦

C

for 2 h, atomic silver was observed, reflected by the diffraction peaks on the XRD

pattern assigned to silver crystals at 2

θ

=

38

.

35, 44.70, 64.60, and 77

.

60

◦

for (111),

(200), (220), and (311) (Figure 12.8). At higher loadings (10.7 and 17.5 wt%), the

diffraction peaks were much stronger and sharper, indicating that the Ag particles were

bigger (Figure 12.8c and d). The diffraction peaks of CNXL, although slightly collapsed,

have been observed for all the samples. This process (at 200

◦

C in air) does not collapse

the crystallinity of the CNXL and reduce silver ions to silver nanoparticles.

Figure 12.9 reveals microscopic images of metal/CNXL composites treated at 200

◦

C

for 2 h in air. Low loadings (3.1 wt%) of silver clearly retain the structure and mor-

phology of the original CNXL (not shown here). The sparsely dispersed particles were

5-10 nm in size. However, it is hard to observe silver metal on the surface by FESEM.

There are a large number of silver particles on the CNXL surface in case of large silver

(d)

(c)

(b)

(a)

10

20

30

40

50

60

70

80

2

q

Figure 12.8

XRD traces of Ag/CNXL composites as function of Ag loading after thermal

treatmentat200

◦

Cfor2h; (a)3.1wt%as-prepared,(b)3.1, (c)10.7,and(d)17.5wt%.

Search WWH ::

Custom Search